This content is password-protected. To view it, please enter the password below.

]]>

This content is password-protected. To view it, please enter the password below.

]]>

Partner Profile:

Chinmay & Tanmay Samak,

Clemson University Automotive Engineering

November 24, 2025

Partner Profile:

Chinmay & Tanmay Samak,

Clemson University Automotive Engineering

November 24, 2025

A digital twin uses real-world data to power a virtual counterpart—an idea reshaping modern engineering. For Chinmay and Tanmay Samak, mirrored counterparts is not only the focus of their research at the Clemson University International Center for Automotive Research (CU-ICAR), it’s also their daily experience as twins who are identical in virtually every way.

Building Blocks

Natives of Pune, India, Chinmay and Tanmay have always known what they have in common truly makes them unique. “It’s always been fun to have a twin, especially one that resonates with you,” said Chinmay. “Twins generally get compared constantly so they choose a mechanism for growing apart or at least a way to differentiate themselves, but that hasn’t been our experience.”

From favorite foods to hobbies, and even their favorite color, the Samak twins have no answer for the common question of how to differentiate them. “We’ve been together since day one and hope to keep it that way,” said Tanmay with a smile.

At a young age their shared interests included activities like cycling, hiking and tinkering in the field of robotics. What began in 8th grade as building line-following and obstacle-avoidance robots grew into research publications and consecutive first place finishes in NASA’s space settlement design competition. By the time they reached their undergraduate studies, they found another shared fascination: autonomous ground vehicles—a passion that would eventually bring them across the world to Greenville, South Carolina.

Simulation to Reality

When considering graduate programs, the brothers developed their own unique criteria to complement university rankings and notoriety.

- A strong academic program in automotive engineering, autonomy, and robotics

- A direct path into a fully funded PhD program

- Access to full-scale test vehicles and state-of-the-art equipment

- An opportunity to work together, in the same lab, under the same advisor

Despite having never visited, they chose Clemson University, and specifically the Automotive Engineering program located at CU-ICAR. Three and a half years later, they are nearing the completion of their PhDs, with both focused on advancing digital twin technology. Working in the Automation, Robotics and Mechatronics (ARM) Lab under Dr. Venkat Krovi, they are helping to close the loop between real-world vehicle behavior and high-precision simulation. Tanmay specializes in translating real-world data into accurate virtual models. Chinmay’s work mirrors this from the opposite direction, ensuring simulation results can be transferred reliably to physical vehicles.

Looking back on their decision, Chinmay shared what he’d tell their 2022 selves: “In a simple statement, what you are dreaming of is about to come true.”

Unexpected Variables

Due to COVID-19, the twins arrived in Greenville knowing Dr. Krovi and CU-ICAR only through digital imagery, articles and virtual interviews. Their real-world experience far exceeded expectations.

Being welcomed with hands-on access to the Open Connected and Automated Vehicle (OpenCAV) during their first weeks on campus, months earlier than expected, made it clear they had found the mentor they hoped for. “Dr. Krovi is the ideal advisor, especially for us,” said Chinmay. “He’s provided the technical and academic direction for areas where he knows we need to learn and also given us the freedom to explore on our own and approach him when we need guidance.”

The positive surprises extended out of the lab as they began to explore the CU-ICAR campus and the surrounding Greenville community. “CU-ICAR has all the right people on campus,” noted Tanmay. “You have students, professors, and industry professionals, and they’re all headed towards the same objectives. No matter who you’re working with, you can’t go wrong.”

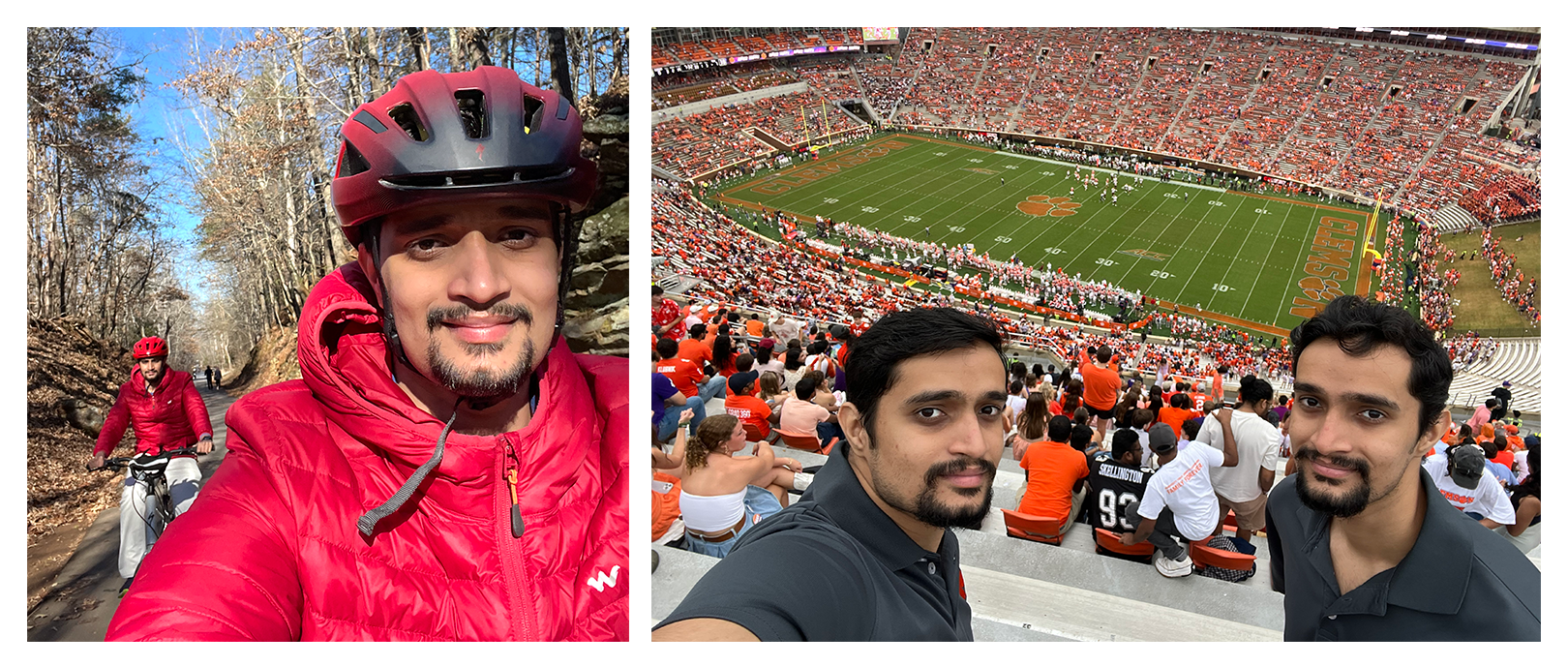

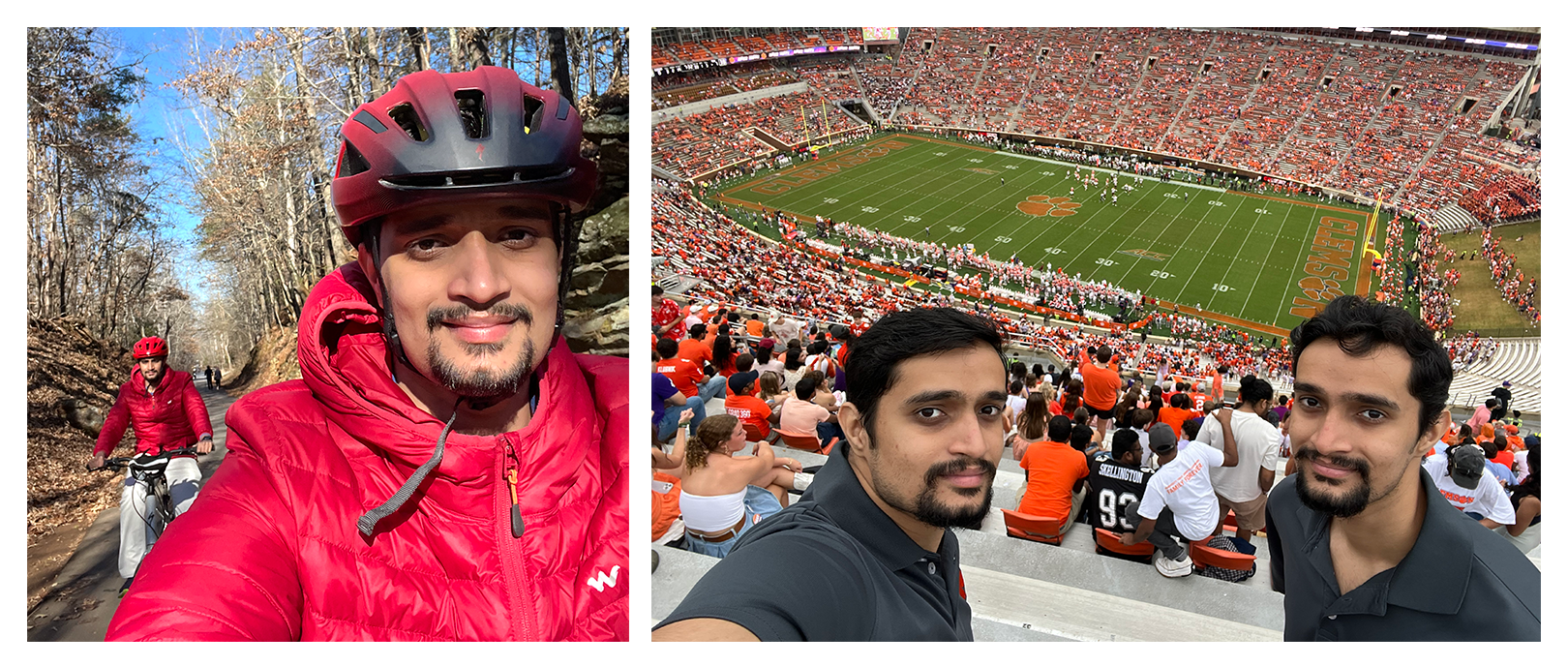

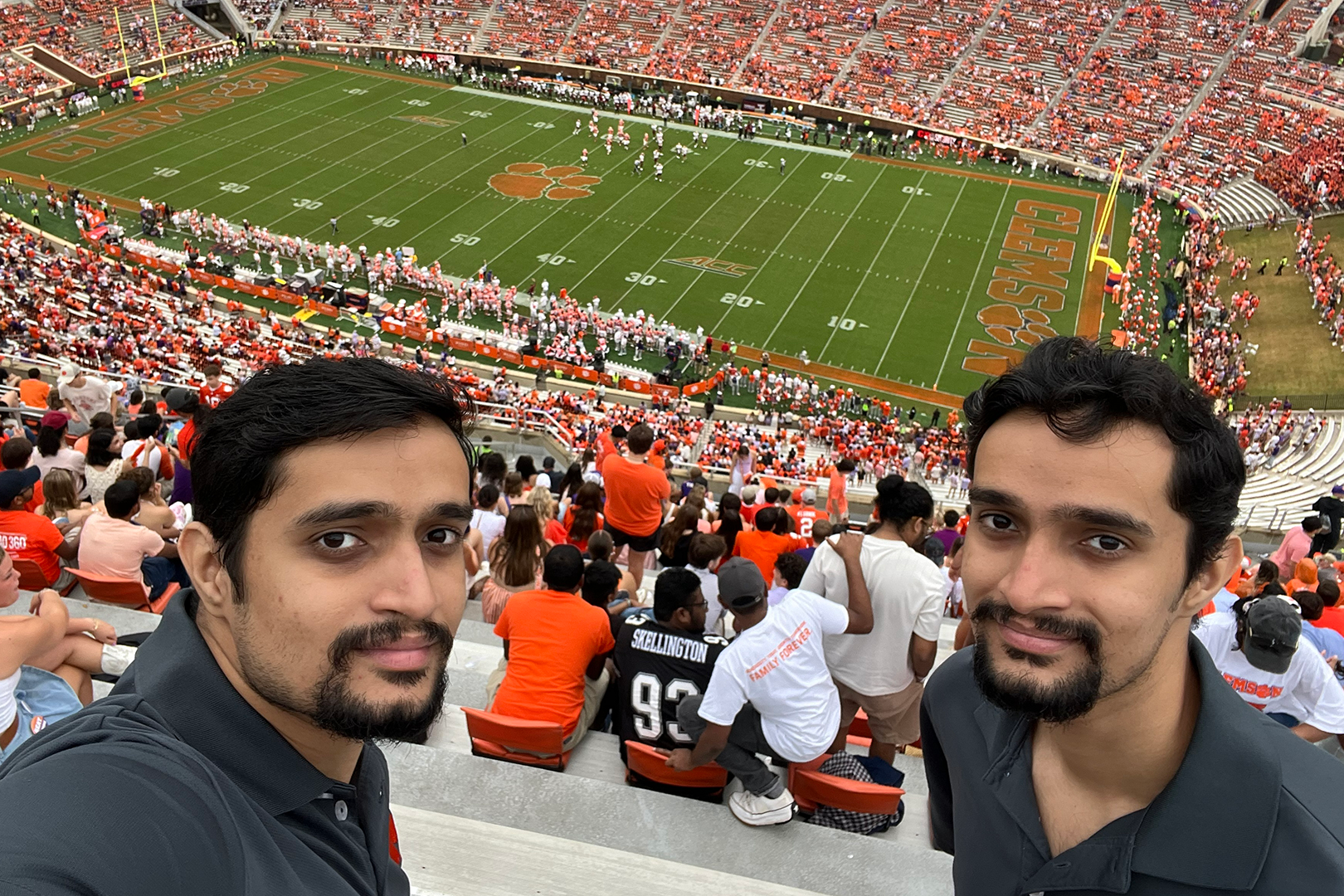

Off campus, Greenville quickly became their second home, one they describe as the perfect balance of modern and tranquil. They fell in love with the mild weather, vibrant downtown, access to nature, and as cyclists, the city’s 28-mile greenway known as the Swamp Rabbit Trail.

The Path Ahead

Within the next year, Chinmay and Tanmay will add “Clemson graduate” to their list of accomplishments. From there, they hope to stay connected to academia while also joining industry through startup ventures. They plan to continue growing their online presence as the Tinker Twins and expand AutoDRIVE, the digital twin ecosystem they created together.

While the exact path ahead is still unfolding, one thing remains certain:

“Whatever it is, most importantly, we’ll do it together.”

A digital twin uses real-world data to power a virtual counterpart—an idea reshaping modern engineering. For Chinmay and Tanmay Samak, mirrored counterparts is not only the focus of their research at the Clemson University International Center for Automotive Research (CU-ICAR), it’s also their daily experience as twins who are identical in virtually every way.

Building Blocks

Natives of Pune, India, Chinmay and Tanmay have always known what they have in common truly makes them unique. “It’s always been fun to have a twin, especially one that resonates with you,” said Chinmay. “Twins generally get compared constantly so they choose a mechanism for growing apart or at least a way to differentiate themselves, but that hasn’t been the case for us.”

From favorite foods to hobbies, and even their favorite color, the Samak twins have no answer for the common question of how to differentiate them. “We’ve been together since day one and hope to keep it that way,” said Tanmay with a smile.

At a young age their shared interests included activities like swimming, cycling, hiking and tinkering in the field of robotics. What began in 8th grade as building line-following and obstacle-avoidance robots grew into research publications and consecutive first place finishes in NASA’s space settlement design competition. By the time they reached their undergraduate studies, they found another shared fascination: autonomous ground vehicles—a passion that would eventually bring them across the world to Greenville, South Carolina.

Simulation to Reality

When considering graduate programs, the brothers developed their own unique criteria to complement university rankings and notoriety.

- A strong academic program in automotive engineering, autonomy, and robotics

- A direct path into a fully funded PhD program

- Access to full-scale test vehicles and state of the art equipment

- An opportunity to work together, in the same lab, under the same advisor

Despite having never visited, they chose Clemson University, and specifically the Automotive Engineering program located at CU-ICAR. Three and a half years later, they are nearing the completion of their PhDs, with both focused on advancing digital twin technology. Working in the Automation, Robotics and Mechatronics (ARM) Lab under Dr. Venkat Krovi, they are helping to close the loop between real-world vehicle behavior and high-precision simulation. Tanmay specializes in translating real-world data into accurate virtual models. Chinmay’s work mirrors this from the opposite direction, ensuring simulation results can be transferred reliably to physical vehicles.

Looking back on their decision, Chinmay shared what he’d tell their 2022 selves: “In a simple statement, what you are dreaming of is about to come true.”

Unexpected Variables

Due to COVID-19, the twins arrived in Greenville knowing Dr. Krovi and CU-ICAR only through digital imagery, articles and virtual interviews. Their real-world experience far exceeded expectations.

Being welcomed with hands-on access to the Open Connected and Automated Vehicle (OpenCAV) during their first weeks on campus, months earlier than expected, made it clear they had found the mentor they hoped for. “Dr. Krovi is the ideal advisor, especially for us,” said Chinmay. “He’s provided the technical and academic direction for areas where he knows we need to learn and also given us the freedom to explore on our own and approach him when we need guidance.”

The positive surprises extended out of the lab as they began to explore the CU-ICAR campus and the surrounding Greenville community. “CU-ICAR has all the right people on campus,” noted Tanmay. “You have students, professors, and industry professionals, and they’re all headed towards the same objectives. No matter who you’re working with, you can’t go wrong.”

Off campus, Greenville quickly became their second home, one they describe as the perfect balance of modern and tranquil. They fell in love with the mild weather, vibrant downtown, access to nature, and as cyclists, the city’s 28-mile greenway known as the Swamp Rabbit Trail.

The Path Ahead

Within the next year, Chinmay and Tanmay will add “Clemson graduate” to their list of accomplishments. From there, they hope to stay connected to academia while also joining industry through startup ventures. They plan to continue growing their online presence as the Tinker Twins and expand AutoDRIVE, the digital twin ecosystem they created together.

While the exact path ahead is still unfolding, one thing remains certain:

“Whatever it is, most importantly, we’ll do it together.”

A digital twin uses real-world data to power a virtual counterpart—an idea reshaping modern engineering. For Chinmay and Tanmay Samak, mirrored counterparts is not only the focus of their research at the Clemson University International Center for Automotive Research (CU-ICAR), it’s also their daily experience as twins who are identical in virtually every way.

Building Blocks

Natives of Pune, India, Chinmay and Tanmay have always known what they have in common truly makes them unique. “It’s always been fun to have a twin, especially one that resonates with you,” said Chinmay. “Twins generally get compared constantly so they choose a mechanism for growing apart or at least a way to differentiate themselves, but that hasn’t been the case for us.”

From favorite foods to hobbies, and even their favorite color, the Samak twins have no answer for the common question of how to differentiate them. “We’ve been together since day one and hope to keep it that way,” said Tanmay with a smile.

At a young age their shared interests included activities like swimming, cycling, hiking and tinkering in the field of robotics. What began in 8th grade as building line-following and obstacle-avoidance robots grew into research publications and consecutive first place finishes in NASA’s space settlement design competition. By the time they reached their undergraduate studies, they found another shared fascination: autonomous ground vehicles—a passion that would eventually bring them across the world to Greenville, South Carolina.

Simulation to Reality

When considering graduate programs, the brothers developed their own unique criteria to complement university rankings and notoriety.

- A strong academic program in automotive engineering, autonomy, and robotics

- A direct path into a fully funded PhD program

- Access to full-scale test vehicles and state-of-the-art equipment

- An opportunity to work together, in the same lab, under the same advisor

Despite having never visited, they chose Clemson University, and specifically the Automotive Engineering program located at CU-ICAR. Three and a half years later, they are nearing the completion of their PhDs, with both focused on advancing digital twin technology. Working in the Automation, Robotics and Mechatronics (ARM) Lab under Dr. Venkat Krovi, they are helping to close the loop between real-world vehicle behavior and high-precision simulation. Tanmay specializes in translating real-world data into accurate virtual models. Chinmay’s work mirrors this from the opposite direction, ensuring simulation results can be transferred reliably to physical vehicles.

Looking back on their decision, Chinmay shared what he’d tell their 2022 selves: “In a simple statement, what you are dreaming of is about to come true.”

Unexpected Variables

Due to COVID-19, the twins arrived in Greenville knowing Dr. Krovi and CU-ICAR only through digital imagery, articles and virtual interviews. Their real-world experience far exceeded expectations.

Being welcomed with hands-on access to the Open Connected and Automated Vehicle (OpenCAV) during their first weeks on campus, months earlier than expected, made it clear they had found the mentor they hoped for. “Dr. Krovi is the ideal advisor, especially for us,” said Chinmay. “He’s provided the technical and academic direction for areas where he knows we need to learn and also given us the freedom to explore on our own and approach him when we need guidance.”

The positive surprises extended out of the lab as they began to explore the CU-ICAR campus and the surrounding Greenville community. “CU-ICAR has all the right people on campus,” noted Tanmay. “You have students, professors, and industry professionals, and they’re all headed towards the same objectives. No matter who you’re working with, you can’t go wrong.”

Off campus, Greenville quickly became their second home, one they describe as the perfect balance of modern and tranquil. They fell in love with the mild weather, vibrant downtown, access to nature, and as cyclists, the city’s 28-mile greenway known as the Swamp Rabbit Trail.

The Path Ahead

Within the next year, Chinmay and Tanmay will add “Clemson graduate” to their list of accomplishments. From there, they hope to stay connected to academia while also joining industry through startup ventures. They plan to continue growing their online presence as the Tinker Twins and expand AutoDRIVE, the digital twin ecosystem they created together.

While the exact path ahead is still unfolding, one thing remains certain:

“Whatever it is, most importantly, we’ll do it together.”

Partner Profile:

Max Frantz, JTEKT North America

October 10, 2025

Partner Profile:

Max Frantz, JTEKT North America

October 10, 2025

What began as a personal decision to be closer to family has led Max Frantz to a career that continues to challenge and inspire him—while also allowing space for what matters most outside of work.

New Place, New Possibilities

When Max and his wife made the decision to move from Philadelphia, their goal was simple: be closer to family and raise their children in a place with natural beauty and a strong sense of community. Greenville, South Carolina—tucked against the foothills of the Blue Ridge Mountains—offered just that.

Shortly after relocating, Max accepted a role as a Principal Product Development Engineer with JTEKT North America. The job proved to be a perfect fit. On the new product development team, Max works on the front end of innovation—identifying emerging needs and rapidly building proof-of-concept tests to determine what’s worth pursuing.

Eight years later, that work still excites him. Whether he’s brainstorming new solutions or rolling up his sleeves to build out an early prototype, Max continues to thrive in a role that keeps him engaged and thinking forward.

At home, he finds equal joy in his role as a dad. From family hikes at Paris Mountain State Park to weekends spent at kids’ sporting events, Max is all-in—professionally and personally.

Finding Room to Grow

Over time, Max began to feel a pull toward expanding his technical expertise. His interest in automated systems and advanced mechanical design kept growing, and he wanted to understand not just how things work—but why.

With encouragement and financial support from JTEKT, he enrolled in Clemson University’s Master’s program in Mechanical Engineering. The location made it even more feasible—many of his classes were held at the Carroll A. Campbell Graduate Education Center, located on the CU-ICAR campus, just steps from his office.

“It was incredibly convenient to take classes here at CU-ICAR in Greenville,” Max said. “I could be working in my office at JTEKT, simply walk across the street to class, and then return to the office.”

Left: Max enjoying his role of dad at home with his kids.

Right: Max takes part in the classic back to school tradition on his first day of his graduate coursework.

That proximity made a busy schedule more manageable—but it wasn’t the only benefit of the setting. Being based at CU-ICAR made balancing work, school, and family more manageable. The campus’s practical amenities—like nearby dining options, a fitness center, walking trails, and easy parking—helped Max stay focused, energized, and on schedule throughout his busy days.

Though the logistics were in his favor, the commitment was still demanding. Juggling a full-time role and parenting two young kids while completing graduate coursework wasn’t easy—but Max took it on with a focus geared toward growth.

“I didn’t really feel relief when I finished,” he reflected. “While I’m glad to have time to explore other things, I really enjoyed the process of continual learning.”

Looking Ahead

Since completing his degree, Max has continued to build on what he learned—both in his day-to-day work and through side projects that keep his skills sharp. He’s also taken time to share his perspective with Clemson mechanical engineering students who stop by his office looking for advice or insight into the field.

For Max, learning isn’t limited to the workplace or the classroom—it’s a mindset that carries into all aspects of his life. Whether he’s diving into new engineering challenges, taking on graduate studies, or exploring the outdoors with his family, Max thrives on discovering what’s next. That spirit of curiosity fuels his growth, keeps his work engaging, and helps him create meaningful experiences with the people who matter most.

What began as a personal decision to be closer to family has led Max Frantz to a career that continues to challenge and inspire him—while also allowing space for what matters most outside of work.

New Place, New Possibilities

When Max and his wife made the decision to move from Philadelphia, their goal was simple: be closer to family and raise their children in a place with natural beauty and a strong sense of community. Greenville, South Carolina—tucked against the foothills of the Blue Ridge Mountains—offered just that.

Shortly after relocating, Max accepted a role as a Principal Product Development Engineer with JTEKT North America. The job proved to be a perfect fit. On the new product development team, Max works on the front end of innovation—identifying emerging needs and rapidly building proof-of-concept tests to determine what’s worth pursuing.

Eight years later, that work still excites him. Whether he’s brainstorming new solutions or rolling up his sleeves to build out an early prototype, Max continues to thrive in a role that keeps him engaged and thinking forward.

At home, he finds equal joy in his role as a dad. From family hikes at Paris Mountain State Park to weekends spent at kids’ sporting events, Max is all-in—professionally and personally.

Finding Room to Grow

Over time, Max began to feel a pull toward expanding his technical expertise. His interest in automated systems and advanced mechanical design kept growing, and he wanted to understand not just how things work—but why.

With encouragement and financial support from JTEKT, he enrolled in Clemson University’s Master’s program in Mechanical Engineering. The location made it even more feasible—many of his classes were held at the Carroll A. Campbell Graduate Education Center, located on the CU-ICAR campus, just steps from his office.

“It was incredibly convenient to take classes here at CU-ICAR in Greenville,” Max said. “I could be working in my office at JTEKT, simply walk across the street to class, and then return to the office.”

Left: Max enjoying his role of dad at home with his kids.

Right: Max takes part in the classic back to school tradition on his first day of his graduate coursework.

That proximity made a busy schedule more manageable—but it wasn’t the only benefit of the setting. Being based at CU-ICAR made balancing work, school, and family more manageable. The campus’s practical amenities—like nearby dining options, a fitness center, walking trails, and easy parking—helped Max stay focused, energized, and on schedule throughout his busy days.

Though the logistics were in his favor, the commitment was still demanding. Juggling a full-time role and parenting two young kids while completing graduate coursework wasn’t easy—but Max took it on with a focus geared toward growth.

“I didn’t really feel relief when I finished,” he reflected. “While I’m glad to have time to explore other things, I really enjoyed the process of continual learning.”

Looking Ahead

Since completing his degree, Max has continued to build on what he learned—both in his day-to-day work and through side projects that keep his skills sharp. He’s also taken time to share his perspective with Clemson mechanical engineering students who stop by his office looking for advice or insight into the field.

For Max, learning isn’t limited to the workplace or the classroom—it’s a mindset that carries into all aspects of his life. Whether he’s diving into new engineering challenges, taking on graduate studies, or exploring the outdoors with his family, Max thrives on discovering what’s next. That spirit of curiosity fuels his growth, keeps his work engaging, and helps him create meaningful experiences with the people who matter most.

What began as a personal decision to be closer to family has led Max Frantz to a career that continues to challenge and inspire him—while also allowing space for what matters most outside of work.

New Place, New Possibilities

When Max and his wife made the decision to move from Philadelphia, their goal was simple: be closer to family and raise their children in a place with natural beauty and a strong sense of community. Greenville, South Carolina—tucked against the foothills of the Blue Ridge Mountains—offered just that.

Shortly after relocating, Max accepted a role as a Principal Product Development Engineer with JTEKT North America. The job proved to be a perfect fit. On the new product development team, Max works on the front end of innovation—identifying emerging needs and rapidly building proof-of-concept tests to determine what’s worth pursuing.

Eight years later, that work still excites him. Whether he’s brainstorming new solutions or rolling up his sleeves to build out an early prototype, Max continues to thrive in a role that keeps him engaged and thinking forward.

At home, he finds equal joy in his role as a dad. From family hikes at Paris Mountain State Park to weekends spent at kids’ sporting events, Max is all-in—professionally and personally.

Max enjoying his role of dad at home with his kids.

Finding Room to Grow

Over time, Max began to feel a pull toward expanding his technical expertise. His interest in automated systems and advanced mechanical design kept growing, and he wanted to understand not just how things work—but why.

With encouragement and financial support from JTEKT, he enrolled in Clemson University’s Master’s program in Mechanical Engineering. The location made it even more feasible—many of his classes were held at the Carroll A. Campbell Graduate Education Center, located on the CU-ICAR campus, just steps from his office.

“It was incredibly convenient to take classes here at CU-ICAR in Greenville,” Max said. “I could be working in my office at JTEKT, simply walk across the street to class, and then return to the office.”

Max takes part in the classic back to school tradition on his first day of his graduate coursework.

That proximity made a busy schedule more manageable—but it wasn’t the only benefit of the setting. Being based at CU-ICAR made balancing work, school, and family more manageable. The campus’s practical amenities—like nearby dining options, a fitness center, walking trails, and easy parking—helped Max stay focused, energized, and on schedule throughout his busy days.

Though the logistics were in his favor, the commitment was still demanding. Juggling a full-time role and parenting two young kids while completing graduate coursework wasn’t easy—but Max took it on with a focus geared toward growth.

“I didn’t really feel relief when I finished,” he reflected. “While I’m glad to have time to explore other things, I really enjoyed the process of continual learning.”

Looking Ahead

Since completing his degree, Max has continued to build on what he learned—both in his day-to-day work and through side projects that keep his skills sharp. He’s also taken time to share his perspective with Clemson mechanical engineering students who stop by his office looking for advice or insight into the field.

For Max, learning isn’t limited to the workplace or the classroom—it’s a mindset that carries into all aspects of his life. Whether he’s diving into new engineering challenges, taking on graduate studies, or exploring the outdoors with his family, Max thrives on discovering what’s next. That spirit of curiosity fuels his growth, keeps his work engaging, and helps him create meaningful experiences with the people who matter most.

This content is password-protected. To view it, please enter the password below.

]]>

VIPR-GS Highlights Impactful Internship Experience For Students

August 28, 2025

By VIPR-GS Intern Kate DeStefano

VIPR-GS Highlights Impactful Internship Experience For Students

August 28, 2025

By VIPR-GS Intern Kate DeStefano

The Virtual Prototyping of Autonomy-Enabled Ground Systems Research Center (VIPR-GS) and Clemson University are celebrating the achievements of its recent fall and spring semester Honors College interns who worked closely with faculty members on advanced research projects involving autonomy, robotics, coding, and engineering.

These internships have provided the students involved with a unique opportunity to gain real-world experience in an academic and research setting. Each project helps to prompt VIPR-GS’s ongoing mission: Create advanced tools for virtual prototyping and agile physical prototyping, driven by research breakthroughs in autonomous off-road vehicles and next-generation propulsion technologies. The initiative also focuses on intelligent fleet energy management, enabling more efficient, adaptable, and sustainable development and deployment of off-road vehicle systems.

The interns collaborated directly with professors on projects involving CAD programs, coding through Python, autonomy kits, creating models, learning sensor setups, and many more exciting and innovative skills.

Jacob Davis, one of the interns that was chosen to work through this program, describes his time as “dynamic and fast-paced”. He said, “As a part of my VIPR internship, I joined Yunyi Jia’s CRA (Collaborative Robotics and Automation) Lab. Over the past semester I have worked on a project involving research for an autonomy kit solution for an industry partner.” Through many hours of research and testing Jacob, accompanied by graduate students in Jia’s lab, was able to “collect and set up a robust array of sensors on the autonomous RZR vehicle for testing autonomy algorithms.”

Jacob Davis validating research in a Polaris RZR equipped for autonomy.

This internship program was designed to prepare students for careers in research, engineering, modeling, simulations, and autonomy. By working side-by-side with Clemson University researchers, interns not only deepened their technical knowledge but also developed soft skills like communication, time-management, and problem-solving.

Katelynn Hughes, an intern who worked closely with Apparao Rao and Greg Mocko to develop her coding and modeling skills said that this opportunity has allowed her to “create a clearer idea of what career I wanted to pursue with my degree.” Internships like this are more than just resume builders, they provide hands-on experience, foster mentorship, and allow students to see firsthand how their academic learning applies in high-impact research environments. Among many things, Katelynn learned how to develop code using Python, Siemens NX, and creating assemblies in different CAD programs.

Throughout the school year, interns also got the opportunity to participate in lab meetings and progress presentations. These experiences specifically help to bridge the gap between classroom learning and practical application. Jeff Fine, Senior Associate Dean of the Clemson University Honors College, said “Internships are excellent opportunities for students to expand their networks and explore potential careers. Our top students and alumni often talk about how an internship experience helped them figure out what they want to do or in some cases what they don’t want to do. Both outcomes are invaluable for students to find their passion and their path.”

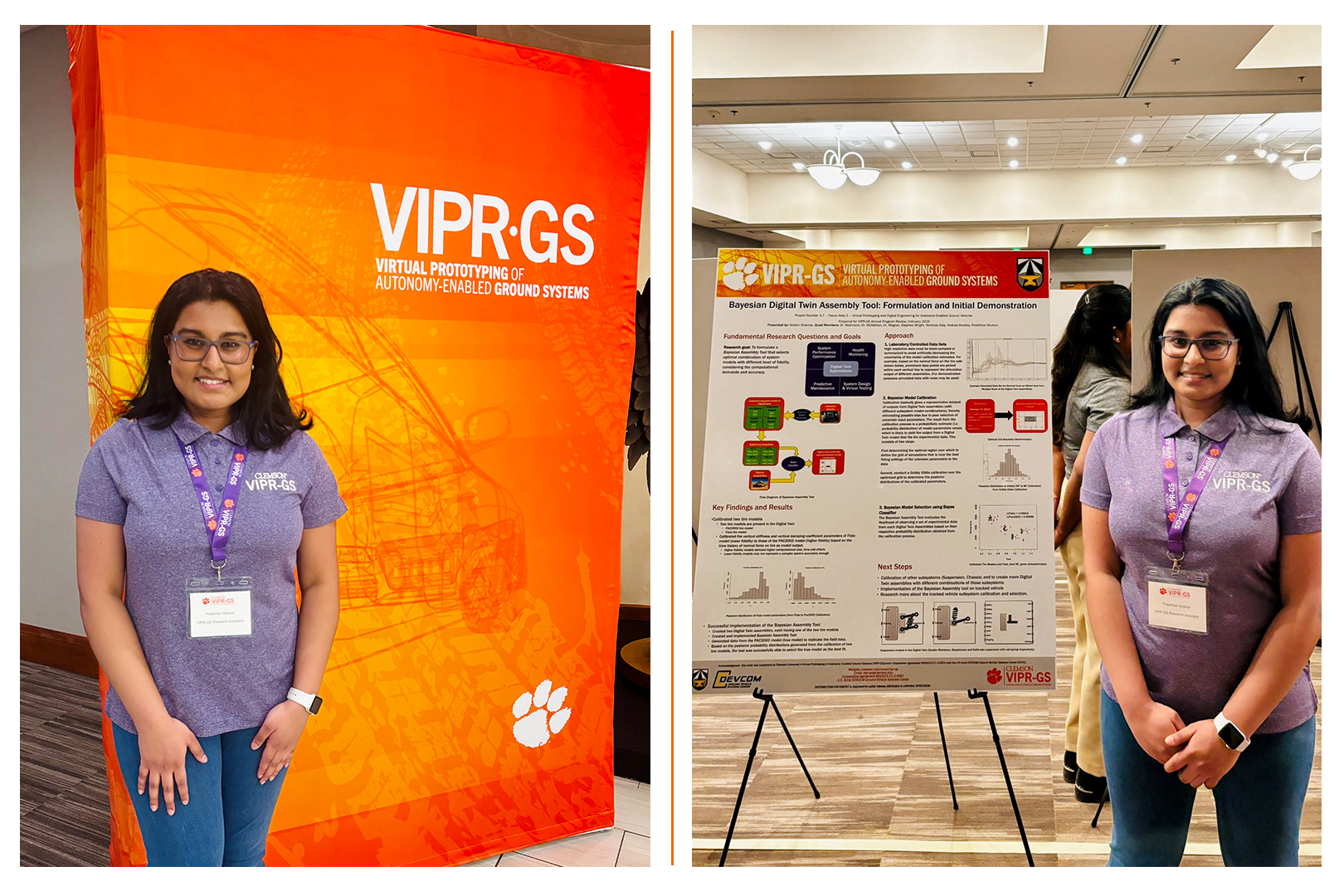

Preethika Yetukuri presented research findings at the VIPR-GS Research Center annual review.

According to The Princeton Review, Clemson University was ranked 11th nationally for “best public schools for internship opportunities.” This recognition highlights Clemson’s strong focus on experiential learning, career readiness, and its commitment to connecting students with real-world professional experiences that prepare them for life after graduation.

As the program looks ahead, VIPR-GS is committed to expanding internship opportunities and strengthening partnerships across disciplines and institutions to support future cohorts of student researchers.

Learn more about the VIPR-GS Research Center here.

Acknowledgment: This work was supported by Clemson University’s Virtual Prototyping of Autonomy Enabled Ground Systems (VIPR-GS), under Cooperative Agreement W56HZV-21-2-0001 with the US Army DEVCOM Ground Vehicle Systems Center (GVSC).

The Virtual Prototyping of Autonomy-Enabled Ground Systems Research Center Center (VIPR-GS) and Clemson University are celebrating the achievements of its recent fall and spring semester Honors College interns who worked closely with faculty members on advanced research projects involving autonomy, robotics, coding, and engineering.

These internships have provided the students involved with a unique opportunity to gain real-world experience in an academic and research setting. Each project helps to prompt VIPR-GS’s ongoing mission: Create advanced tools for virtual prototyping and agile physical prototyping, driven by research breakthroughs in autonomous off-road vehicles and next-generation propulsion technologies. The initiative also focuses on intelligent fleet energy management, enabling more efficient, adaptable, and sustainable development and deployment of off-road vehicle systems.

The interns collaborated directly with professors on projects involving CAD programs, coding through Python, autonomy kits, creating models, learning sensor setups, and many more exciting and innovative skills.

Jacob Davis, one of the interns that was chosen to work through this program, describes his time as “dynamic and fast-paced”. He said, “As a part of my VIPR internship, I joined Yunyi Jia’s CRA (Collaborative Robotics and Automation) Lab. Over the past semester I have worked on a project involving research for an autonomy kit solution for an industry partner.” Through many hours of research and testing Jacob, accompanied by graduate students in Jia’s lab, was able to “collect and set up a robust array of sensors on the autonomous RZR vehicle for testing autonomy algorithms.”

Jacob Davis validating research in a Polaris RZR equipped for autonomy.

This internship program was designed to prepare students for careers in research, engineering, modeling, simulations, and autonomy. By working side-by-side with Clemson University researchers, interns not only deepened their technical knowledge but also developed soft skills like communication, time-management, and problem-solving.

Katelynn Hughes, an intern who worked closely with Apparao Rao and Greg Mocko to develop her coding and modeling skills said that this opportunity has allowed her to “create a clearer idea of what career I wanted to pursue with my degree.” Internships like this are more than just resume builders, they provide hands-on experience, foster mentorship, and allow students to see firsthand how their academic learning applies in high-impact research environments. Among many things, Katelynn learned how to develop code using Python, Siemens NX, and creating assemblies in different CAD programs.

Throughout the school year, interns also got the opportunity to participate in lab meetings and progress presentations. These experiences specifically help to bridge the gap between classroom learning and practical application. Jeff Fine, Senior Associate Dean of the Clemson University Honors College, said “Internships are excellent opportunities for students to expand their networks and explore potential careers. Our top students and alumni often talk about how an internship experience helped them figure out what they want to do or in some cases what they don’t want to do. Both outcomes are invaluable for students to find their passion and their path.”

Preethika Yetukuri presented research findings at the VIPR-GS Research Center annual review.

According to The Princeton Review, Clemson University was ranked 11th nationally for “best public schools for internship opportunities.” This recognition highlights Clemson’s strong focus on experiential learning, career readiness, and its commitment to connecting students with real-world professional experiences that prepare them for life after graduation.

As the program looks ahead, VIPR-GS is committed to expanding internship opportunities and strengthening partnerships across disciplines and institutions to support future cohorts of student researchers.

Learn more about the VIPR-GS Research Center here.

Acknowledgment: This work was supported by Clemson University’s Virtual Prototyping of Autonomy Enabled Ground Systems (VIPR-GS), under Cooperative Agreement W56HZV-21-2-0001 with the US Army DEVCOM Ground Vehicle Systems Center (GVSC).

The Virtual Prototyping of Autonomy-Enabled Ground Systems Research Center (VIPR-GS) and Clemson University are celebrating the achievements of its recent fall and spring semester Honors College interns who worked closely with faculty members on advanced research projects involving autonomy, robotics, coding, and engineering.

These internships have provided the students involved with a unique opportunity to gain real-world experience in an academic and research setting. Each project helps to prompt VIPR-GS’s ongoing mission: Create advanced tools for virtual prototyping and agile physical prototyping, driven by research breakthroughs in autonomous off-road vehicles and next-generation propulsion technologies. The initiative also focuses on intelligent fleet energy management, enabling more efficient, adaptable, and sustainable development and deployment of off-road vehicle systems.

The interns collaborated directly with professors on projects involving CAD programs, coding through Python, autonomy kits, creating models, learning sensor setups, and many more exciting and innovative skills.

Jacob Davis, one of the interns that was chosen to work through this program, describes his time as “dynamic and fast-paced”. He said, “As a part of my VIPR internship, I joined Yunyi Jia’s CRA (Collaborative Robotics and Automation) Lab. Over the past semester I have worked on a project involving research for an autonomy kit solution for an industry partner.” Through many hours of research and testing Jacob, accompanied by graduate students in Jia’s lab, was able to “collect and set up a robust array of sensors on the autonomous RZR vehicle for testing autonomy algorithms.”

Jacob Davis validating research in a Polaris RZR equipped for autonomy.

This internship program was designed to prepare students for careers in research, engineering, modeling, simulations, and autonomy. By working side-by-side with Clemson University researchers, interns not only deepened their technical knowledge but also developed soft skills like communication, time-management, and problem-solving.

Katelynn Hughes, an intern who worked closely with Apparao Rao and Greg Mocko to develop her coding and modeling skills said that this opportunity has allowed her to “create a clearer idea of what career I wanted to pursue with my degree.” Internships like this are more than just resume builders, they provide hands-on experience, foster mentorship, and allow students to see firsthand how their academic learning applies in high-impact research environments. Among many things, Katelynn learned how to develop code using Python, Siemens NX, and creating assemblies in different CAD programs.

Throughout the school year, interns also got the opportunity to participate in lab meetings and progress presentations. These experiences specifically help to bridge the gap between classroom learning and practical application. Jeff Fine, Senior Associate Dean of the Clemson University Honors College, said “Internships are excellent opportunities for students to expand their networks and explore potential careers. Our top students and alumni often talk about how an internship experience helped them figure out what they want to do or in some cases what they don’t want to do. Both outcomes are invaluable for students to find their passion and their path.”

Preethika Yetukuri presented research findings at the VIPR-GS Research Center annual review.

According to The Princeton Review, Clemson University was ranked 11th nationally for “best public schools for internship opportunities.” This recognition highlights Clemson’s strong focus on experiential learning, career readiness, and its commitment to connecting students with real-world professional experiences that prepare them for life after graduation.

As the program looks ahead, VIPR-GS is committed to expanding internship opportunities and strengthening partnerships across disciplines and institutions to support future cohorts of student researchers.

Learn more about the VIPR-GS Research Center here.

Acknowledgment: This work was supported by Clemson University’s Virtual Prototyping of Autonomy Enabled Ground Systems (VIPR-GS), under Cooperative Agreement W56HZV-21-2-0001 with the US Army DEVCOM Ground Vehicle Systems Center (GVSC).

Gregory Mocko to lead Clemson University’s Deep Orange program

August 15, 2025

Gregory Mocko to lead Clemson University’s Deep Orange program

August 15, 2025

Gregory Mocko, associate professor of mechanical engineering and a champion of industry-driven education, has been named director of Clemson University’s acclaimed Deep Orange program, effective Aug. 15.

Mocko takes the wheel from Rob Prucka, who will turn more attention toward departmental leadership and the VIPR-GS program. Mocko’s appointment puts a seasoned educator, innovator and industry collaborator at the helm of one of the nation’s most distinctive automotive engineering initiatives.

Deep Orange is a prototype vehicle program that is part of the automotive engineering degree curriculum and based at the Clemson University International Center for Automotive Research (CU-ICAR).

Over two years, graduate students in automotive engineering work with faculty and major industry sponsors to design, build and debut a concept vehicle. BMW, Toyota, General Motors, Honda R&D Americas, Ford, Mazda, ExxonMobil, NVIDIA, and the U.S. Army are among the companies that have backed Deep Orange projects.

As Deep Orange director, Mocko will oversee the program’s strategic vision, guide students through each project’s lifecycle and strengthen faculty and industry partnerships.

Mocko, a Clemson faculty member since 2006, has built his career on connecting students with real-world engineering challenges. He formerly coordinated Clemson’s Mechanical Engineering Capstone Design Program and has overseen ambitious projects such as a nationwide student collaboration to design, build, and fly an unmanned aerial vehicle modeled on Boeing’s Dreamliner assembly approach.

Mocko’s research spans model-based systems engineering, AI in engineering design, and advanced manufacturing, and he has published more than 70 peer-reviewed articles.

Laine Mears, director of the School of Mechanical and Automotive Engineering, said that Mocko is ready to take on the current Deep Orange 17 program and begin defining future Deep Orange projects, noting that his nearly two decades of design research and practical application experience will serve Deep Orange well.

“Dr. Mocko brings a fresh perspective and a rich background in connecting students and industry, using innovative programs as the bridge,” Mears said. “He is highly regarded by his students and his colleagues. With him in the driver’s seat, Deep Orange is well positioned to go farther and faster!”

Gregory Mocko, associate professor of mechanical engineering and a champion of industry-driven education, has been named director of Clemson University’s acclaimed Deep Orange program, effective Aug. 15.

Mocko takes the wheel from Rob Prucka, who will turn more attention toward departmental leadership and the VIPR-GS program. Mocko’s appointment puts a seasoned educator, innovator and industry collaborator at the helm of one of the nation’s most distinctive automotive engineering initiatives.

Deep Orange is a prototype vehicle program that is part of the automotive engineering degree curriculum and based at the Clemson University International Center for Automotive Research (CU-ICAR).

Over two years, graduate students in automotive engineering work with faculty and major industry sponsors to design, build and debut a concept vehicle. BMW, Toyota, General Motors, Honda R&D Americas, Ford, Mazda, ExxonMobil, NVIDIA, and the U.S. Army are among the companies that have backed Deep Orange projects.

As Deep Orange director, Mocko will oversee the program’s strategic vision, guide students through each project’s lifecycle and strengthen faculty and industry partnerships.

Mocko, a Clemson faculty member since 2006, has built his career on connecting students with real-world engineering challenges. He formerly coordinated Clemson’s Mechanical Engineering Capstone Design Program and has overseen ambitious projects such as a nationwide student collaboration to design, build, and fly an unmanned aerial vehicle modeled on Boeing’s Dreamliner assembly approach.

Mocko’s research spans model-based systems engineering, AI in engineering design, and advanced manufacturing, and he has published more than 70 peer-reviewed articles.

Laine Mears, director of the School of Mechanical and Automotive Engineering, said that Mocko is ready to take on the current Deep Orange 17 program and begin defining future Deep Orange projects, noting that his nearly two decades of design research and practical application experience will serve Deep Orange well.

“Dr. Mocko brings a fresh perspective and a rich background in connecting students and industry, using innovative programs as the bridge,” Mears said. “He is highly regarded by his students and his colleagues. With him in the driver’s seat, Deep Orange is well positioned to go farther and faster!”

Gregory Mocko, associate professor of mechanical engineering and a champion of industry-driven education, has been named director of Clemson University’s acclaimed Deep Orange program, effective Aug. 15.

Mocko takes the wheel from Rob Prucka, who will turn more attention toward departmental leadership and the VIPR-GS program. Mocko’s appointment puts a seasoned educator, innovator and industry collaborator at the helm of one of the nation’s most distinctive automotive engineering initiatives.

Deep Orange is a prototype vehicle program that is part of the automotive engineering degree curriculum and based at the Clemson University International Center for Automotive Research (CU-ICAR).

Over two years, graduate students in automotive engineering work with faculty and major industry sponsors to design, build and debut a concept vehicle. BMW, Toyota, General Motors, Honda R&D Americas, Ford, Mazda, ExxonMobil, NVIDIA, and the U.S. Army are among the companies that have backed Deep Orange projects.

As Deep Orange director, Mocko will oversee the program’s strategic vision, guide students through each project’s lifecycle and strengthen faculty and industry partnerships.

Mocko, a Clemson faculty member since 2006, has built his career on connecting students with real-world engineering challenges. He formerly coordinated Clemson’s Mechanical Engineering Capstone Design Program and has overseen ambitious projects such as a nationwide student collaboration to design, build, and fly an unmanned aerial vehicle modeled on Boeing’s Dreamliner assembly approach.

Mocko’s research spans model-based systems engineering, AI in engineering design, and advanced manufacturing, and he has published more than 70 peer-reviewed articles.

Laine Mears, director of the School of Mechanical and Automotive Engineering, said that Mocko is ready to take on the current Deep Orange 17 program and begin defining future Deep Orange projects, noting that his nearly two decades of design research and practical application experience will serve Deep Orange well.

“Dr. Mocko brings a fresh perspective and a rich background in connecting students and industry, using innovative programs as the bridge,” Mears said. “He is highly regarded by his students and his colleagues. With him in the driver’s seat, Deep Orange is well positioned to go farther and faster!”

Clemson University Unveils Deep Orange 16: A Semi-Autonomous, Off-Road Rapid Response Vehicle

August 12, 2025

Clemson University Unveils Deep Orange 16: A Semi-Autonomous, Off-Road Rapid Response Vehicle

August 12, 2025

Clemson University has unveiled Deep Orange 16, a next-generation, semi-autonomous vehicle designed to transform emergency response in extreme conditions. Developed by graduate automotive engineering students in the university’s acclaimed Deep Orange program, the vehicle merges advanced technology with mission-critical functionality to enhance the speed, safety, and efficiency of rescue operations.

Sponsored by the Virtual Prototyping of Autonomy-Enabled Ground Systems (VIPR-GS) Research Center and developed in collaboration with the U.S. Army and other strategic partners, Deep Orange 16 is engineered to tackle some of the toughest challenges in high-risk rescue scenarios—reducing response time while limiting the number of personnel needed in the field.

Mission-Driven Design

Inspired by the real-world challenges faced during Hurricane Helene, the Deep Orange 16 team engineered the vehicle to support critical disaster response efforts. On its outbound journey, the vehicle can deliver a full pallet of emergency supplies to affected areas. For the return trip, the vehicle operates autonomously—transporting up to six individuals, including injured passengers, to safety. Capable of reaching the scene within the “golden hour,” the vehicle also generates a high-resolution digital terrain map for the autonomous return, allowing the original driver to remain on-site and assist ongoing rescue efforts.

Engineered for the Elements

- High-speed, semi-autonomous vehicle with a 350-kilometer range and off-road capabilities built for unpredictable terrain.

- Series hybrid powertrain enables continuous battery charging to extend range and supports near-silent operation for special mission scenarios.

- Designed for real-time deployment, Deep Orange 16 features a lightweight, weatherproof exterior engineered for reliable operation in a variety of environmental conditions.

Innovative Monitoring

- A 360-degree camera system provides full situational awareness, including tire-level views for obstacle detection.

- An AI-powered heads-up display alerts drivers to hazards up to 100 feet away, enhancing navigation and safety.

- Onboard medical monitoring tracks patient vitals in real time, including temperature, heart rate, and perspiration during transport.

Rescue-Ready Interior

- Interior accommodates the transport of six people, including a rotating passenger seat to support multiple operational roles.

- Ergonomic litter loader streamlines patient or supply loading.

- MOLLE storage system offers secure, modular organization of rescue and medical gear.

- Rear hatch fits a standard pallet of supplies, while the clam-shell design enables flexible loading of oversized cargo.

- Integrated exterior compartments securely transport fire rescue equipment.

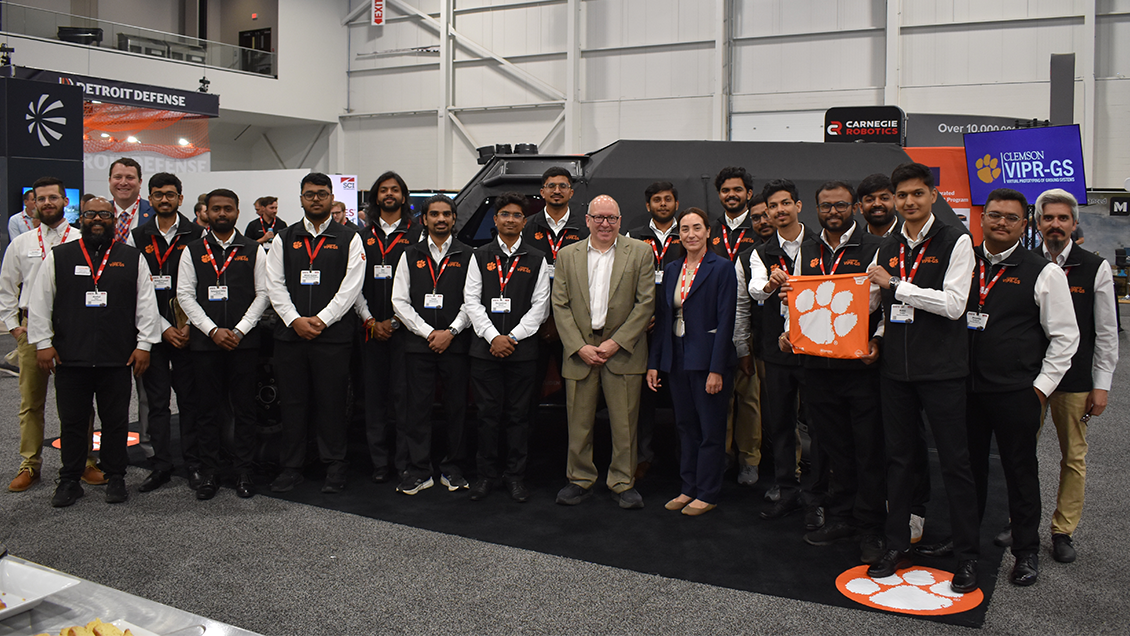

Deep Orange 16 students and staff with their prototype vehicle on the CU-ICAR campus.

Developing Industry Leaders

Deep Orange 16 showcases the innovation, technical expertise, and dedication of the 17-member team of graduate students from Clemson’s automotive engineering program. “Deep Orange pushes us to think like real-world engineers,” said team lead Rohit Godse. “We are not just learning theory, but solving complex, high-stakes problems that prepare us to lead in the industry from day one.”

From initial concept to fully functional prototype, the team collaborated with the VIPR-GS Research Center, government agencies, and industry partners to solve practical challenges—gaining hands-on experience that prepares them to enter the workforce as industry-ready engineers. “The Deep Orange program demonstrates what’s possible when academia, government, and industry come together to solve real-world problems,” said Dr. Robert Prucka, Kulwicki Endowed Professor and Chair of the Department of Automotive Engineering. “Our students are not only driving innovation—they’re helping to save lives by improving how we respond to emergencies in the most challenging environments.”

Deep Orange 16 was officially unveiled at the Ground Vehicle Systems Engineering & Technology Symposium (GVSETS) in Novi, Michigan. It will now serve as a test and validation platform for ongoing research by the VIPR-GS Research Center, located at the Clemson University International Center for Automotive Research (CU-ICAR) in Greenville, South Carolina.

Acknowledgment: This work was supported by Clemson University’s Virtual Prototyping of Autonomy Enabled Ground Systems (VIPR-GS), under Cooperative Agreement W56HZV-21-2-0001 with the US Army DEVCOM Ground Vehicle Systems Center (GVSC).

DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited. OPSEC9980.

Clemson University has unveiled Deep Orange 16, a next-generation, semi-autonomous vehicle designed to transform emergency response in extreme conditions. Developed by graduate automotive engineering students in the university’s acclaimed Deep Orange program, the vehicle merges advanced technology with mission-critical functionality to enhance the speed, safety, and efficiency of rescue operations.

Sponsored by the Virtual Prototyping of Autonomy-Enabled Ground Systems (VIPR-GS) Research Center and developed in collaboration with the U.S. Army and other strategic partners, Deep Orange 16 is engineered to tackle some of the toughest challenges in high-risk rescue scenarios—reducing response time while limiting the number of personnel needed in the field.

Mission-Driven Design

Inspired by the real-world challenges faced during Hurricane Helene, the Deep Orange 16 team engineered the vehicle to support critical disaster response efforts. On its outbound journey, the vehicle can deliver a full pallet of emergency supplies to affected areas. For the return trip, the vehicle operates autonomously—transporting up to six individuals, including injured passengers, to safety. Capable of reaching the scene within the “golden hour,” the vehicle also generates a high-resolution digital terrain map for the autonomous return, allowing the original driver to remain on-site and assist ongoing rescue efforts.

Engineered for the Elements

- High-speed, semi-autonomous vehicle with a 350-kilometer range and off-road capabilities built for unpredictable terrain.

- Series hybrid powertrain enables continuous battery charging to extend range and supports near-silent operation for special mission scenarios.

- Designed for real-time deployment, Deep Orange 16 features a lightweight, weatherproof exterior engineered for reliable operation in a variety of environmental conditions.

Innovative Monitoring

- A 360-degree camera system provides full situational awareness, including tire-level views for obstacle detection.

- An AI-powered heads-up display alerts drivers to hazards up to 100 feet away, enhancing navigation and safety.

- Onboard medical monitoring tracks patient vitals in real time, including temperature, heart rate, and perspiration during transport.

Rescue-Ready Interior

- Interior accommodates the transport of six people, including a rotating passenger seat to support multiple operational roles.

- Ergonomic litter loader streamlines patient or supply loading.

- MOLLE storage system offers secure, modular organization of rescue and medical gear.

- Rear hatch fits a standard pallet of supplies, while the clam-shell design enables flexible loading of oversized cargo.

- Integrated exterior compartments securely transport fire rescue equipment.

Deep Orange 16 students and staff with their prototype vehicle on the CU-ICAR campus.

Developing Industry Leaders

Deep Orange 16 showcases the innovation, technical expertise, and dedication of the 17-member team of graduate students from Clemson’s automotive engineering program. “Deep Orange pushes us to think like real-world engineers,” said team lead Rohit Godse. “We are not just learning theory, but solving complex, high-stakes problems that prepare us to lead in the industry from day one.”

From initial concept to fully functional prototype, the team collaborated with the VIPR-GS Research Center, government agencies, and industry partners to solve practical challenges—gaining hands-on experience that prepares them to enter the workforce as industry-ready engineers. “The Deep Orange program demonstrates what’s possible when academia, government, and industry come together to solve real-world problems,” said Dr. Robert Prucka, Kulwicki Endowed Professor and Chair of the Department of Automotive Engineering. “Our students are not only driving innovation—they’re helping to save lives by improving how we respond to emergencies in the most challenging environments.”

Deep Orange 16 was officially unveiled at the Ground Vehicle Systems Engineering & Technology Symposium (GVSETS) in Novi, Michigan. It will now serve as a test and validation platform for ongoing research by the VIPR-GS Research Center, located at the Clemson University International Center for Automotive Research (CU-ICAR) in Greenville, South Carolina.

Acknowledgment: This work was supported by Clemson University’s Virtual Prototyping of Autonomy Enabled Ground Systems (VIPR-GS), under Cooperative Agreement W56HZV-21-2-0001 with the US Army DEVCOM Ground Vehicle Systems Center (GVSC).

DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited. OPSEC9980.

Clemson University has unveiled Deep Orange 16, a next-generation, semi-autonomous vehicle designed to transform emergency response in extreme conditions. Developed by graduate automotive engineering students in the university’s acclaimed Deep Orange program, the vehicle merges advanced technology with mission-critical functionality to enhance the speed, safety, and efficiency of rescue operations.

Sponsored by the Virtual Prototyping of Autonomy-Enabled Ground Systems (VIPR-GS) Research Center and developed in collaboration with the U.S. Army and other strategic partners, Deep Orange 16 is engineered to tackle some of the toughest challenges in high-risk rescue scenarios—reducing response time while limiting the number of personnel needed in the field.

Mission-Driven Design

Inspired by the real-world challenges faced during Hurricane Helene, the Deep Orange 16 team engineered the vehicle to support critical disaster response efforts. On its outbound journey, the vehicle can deliver a full pallet of emergency supplies to affected areas. For the return trip, the vehicle operates autonomously—transporting up to six individuals, including injured passengers, to safety. Capable of reaching the scene within the “golden hour,” the vehicle also generates a high-resolution digital terrain map for the autonomous return, allowing the original driver to remain on-site and assist ongoing rescue efforts.

Engineered for the Elements

- High-speed, semi-autonomous vehicle with a 350-kilometer range and off-road capabilities built for unpredictable terrain.

- Series hybrid powertrain enables continuous battery charging to extend range and supports near-silent operation for special mission scenarios.

- Designed for real-time deployment, Deep Orange 16 features a lightweight, weatherproof exterior engineered for reliable operation in a variety of environmental conditions.

Innovative Monitoring

- A 360-degree camera system provides full situational awareness, including tire-level views for obstacle detection.

- An AI-powered heads-up display alerts drivers to hazards up to 100 feet away, enhancing navigation and safety.

- Onboard medical monitoring tracks patient vitals in real time, including temperature, heart rate, and perspiration during transport.

Rescue-Ready Interior

- Interior accommodates the transport of six people, including a rotating passenger seat to support multiple operational roles.

- Ergonomic litter loader streamlines patient or supply loading.

- MOLLE storage system offers secure, modular organization of rescue and medical gear.

- Rear hatch fits a standard pallet of supplies, while the clam-shell design enables flexible loading of oversized cargo.

- Integrated exterior compartments securely transport fire rescue equipment.

Deep Orange 16 students and staff with their prototype vehicle on the CU-ICAR campus.

Developing Industry Leaders

Deep Orange 16 showcases the innovation, technical expertise, and dedication of the 17-member team of graduate students from Clemson’s automotive engineering program. “Deep Orange pushes us to think like real-world engineers,” said team lead Rohit Godse. “We are not just learning theory, but solving complex, high-stakes problems that prepare us to lead in the industry from day one.”

From initial concept to fully functional prototype, the team collaborated with the VIPR-GS Research Center, government agencies, and industry partners to solve practical challenges—gaining hands-on experience that prepares them to enter the workforce as industry-ready engineers. “The Deep Orange program demonstrates what’s possible when academia, government, and industry come together to solve real-world problems,” said Dr. Robert Prucka, Kulwicki Endowed Professor and Chair of the Department of Automotive Engineering. “Our students are not only driving innovation—they’re helping to save lives by improving how we respond to emergencies in the most challenging environments.”

Deep Orange 16 was officially unveiled at the Ground Vehicle Systems Engineering & Technology Symposium (GVSETS) in Novi, Michigan. It will now serve as a test and validation platform for ongoing research by the VIPR-GS Research Center, located at the Clemson University International Center for Automotive Research (CU-ICAR) in Greenville, South Carolina.

Acknowledgment: This work was supported by Clemson University’s Virtual Prototyping of Autonomy Enabled Ground Systems (VIPR-GS), under Cooperative Agreement W56HZV-21-2-0001 with the US Army DEVCOM Ground Vehicle Systems Center (GVSC).

DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited. OPSEC9980.