The MES that boosts your productivity.

Your plant, always under control. Traceability, quality, and efficiency in real time, from the first order to the last delivery.

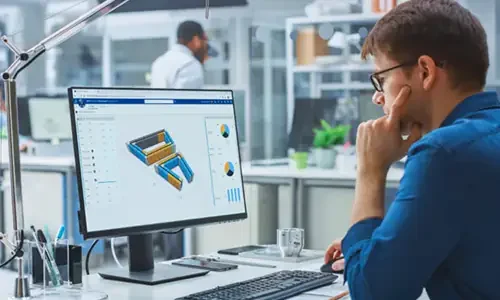

MES Systems: connected plant, informed decisions.

Our MES systems make the difference between assuming and monitoring: every machine, every operator, and every minute… measured, controlled, and optimized.

What isn’t measured, can’t be improved.

UNEXPECTED DOWNTIME

Avoid interruptions that delay your production and keep your line running without surprises.

OPERATING EFFICIENCY (OEE)

Make the most of your resources and machinery, reducing downtime and bottlenecks.

MATERIAL WASTE

Control waste and scrap to make processes more profitable and less frustrating.

DEFECTS AND REWORK

Ensure the quality of your products, avoiding rework and constant inspections.

EXCESS STOCK

Synchronize inventory with production and orders, reducing costs and warehouse overload.

PRODUCTION CAPACITY

Maximize your plant’s performance, achieving visible results day by day.

Our MES is designed for you if…

You want to turn chaos into control

- Identify where your time is going and which orders are most profitable.

- Act on accurate information instead of estimates.

- Improve processes and productivity without relying on spreadsheets.

You need to provide quick responses to clients and management

- Instantly know the status of any order.

- Access plant information without having to go to the machines.

- Respond with reliable data, avoiding errors and confusion.

You want to stop chasing work orders

- See what is being done, who is doing it, and what remains pending.

- Complete control of plant operations, minute by minute.

- Prevent delays and ensure on-time order delivery.

You want to reduce stoppages and delays that increase your production costs

- Anticipate problems in machines, operators, and schedules.

- Minimize resource losses and downtime.

- Keep the plant running at maximum performance.

You believe that paper is no longer practical or competitive

- Record everything digitally, without errors or duplicates.

- Access historical and up-to-date information instantly.

- Centralize data and facilitate coordination between teams.

Connecting your plant is just the first step

Each module of our MES is specifically designed for your industrial processes and solutions.

Production and Plant

Your plant, always under control. Detect any anomaly instantly and act before it affects production. More visibility, fewer surprises.

Traceability

Track every batch, component, and product in detail. Know exactly what has been done, when, and by whom. Avoid errors, non-compliance, and surprises in your plant.

Quality

Ensures products comply with standards. Advanced quality planning (AQP), statistical process control (SPC), non-conformity management (ACCI), calibration and control tool management (CALIBRATOR).

Logistics and Inventory

CMMS Maintenance

Machines ready when you need them. Anticipate failures, reduce breakdowns and ensure your equipment works at its best.

Documentation and Communication

All your information organised and accessible to your team. Forget about paper and spreadsheets: always access the latest version of your documents, avoiding errors and confusion.

Data Analysis

Your figures, in order. Dashboard and alerts that allow you to react quickly and keep the plant running.

Make your teams and systems

work as one

When engineering, the shop floor, and management are connected, the factory moves forward smoothly.

Our MES solutions integrate with your ERP and CAD systems to turn data into decisions and efficiency into profitability.

ERP

Take control of your factory. Integrate your existing processes, streamline decision-making, and access reliable data instantly.

Engineering

Accelerate your team’s innovation. Our engineering solutions foster collaboration and ensure efficient processes with reliable results.

WE SPEAK YOUR LANGUAGE

Our solutions adapt to the processes and challenges of each industry

“Thanks to OLANET, we have achieved a 10% INCREASE in the production plant’s capacity.”

Aitor Barinaga

Chief Operating Officer at Ternua Group

“The flow of information between RPS (ERP system) and OLANET is key to our operations.”

Josu Aranburu

Production and Sales Manager at Arteca

Contact Us

We are here to help you and answer your questions with complete confidence.

Write your inquiry, and we will respond as soon as possible.