Why

PREDICTO

We have created PREDICTO because we believe that predictive maintenance is the future of industrial asset management. We want to make predictive maintenance universal and easy to apply to a wide range of industries.

Future Work

in Manufacturing

Data gathered from all equipment will allow full visibility of the production process / AI will provide different maintenance scenarios based on specific goals / Maintenance teams will be delivering just in time repairs and will never know what unplanned repair means.

Product Info

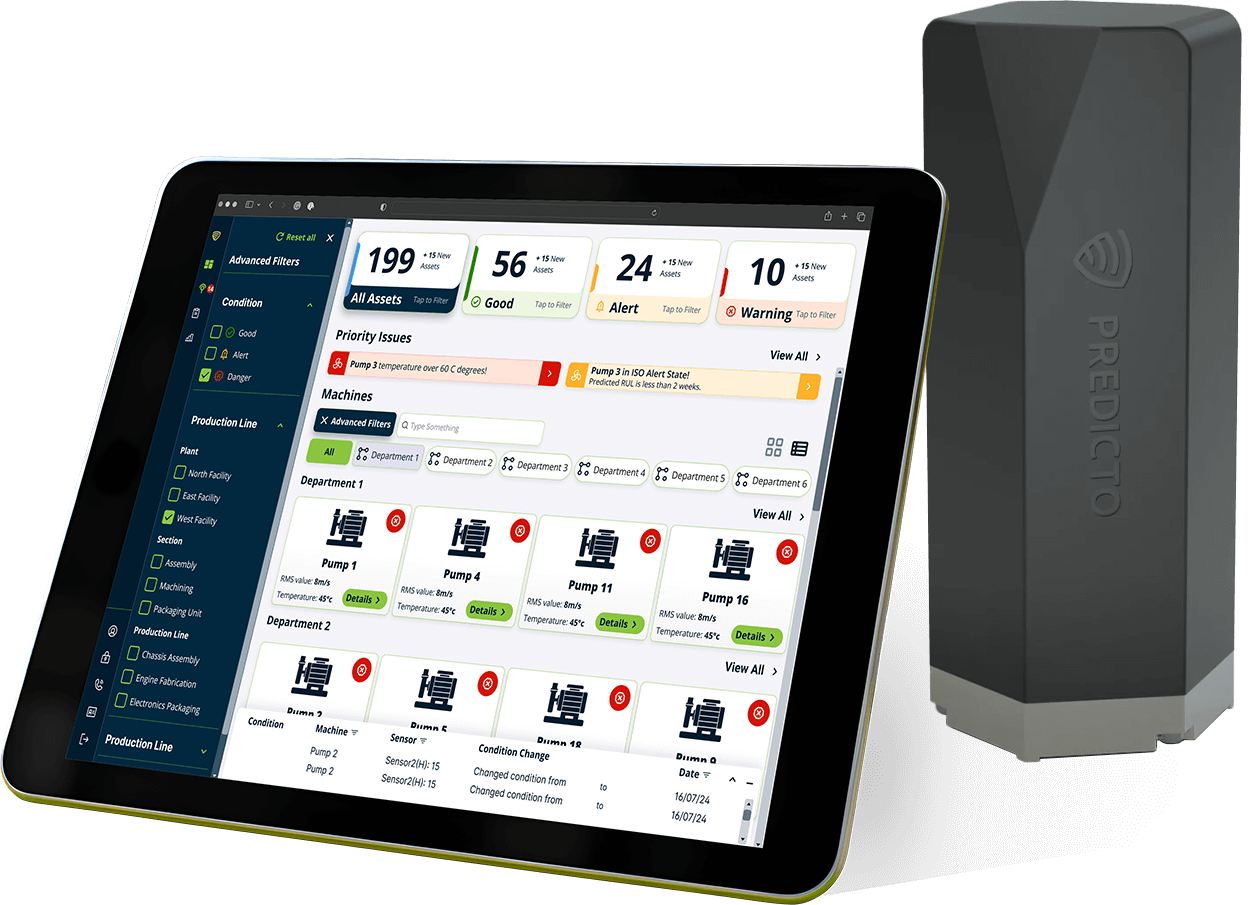

PREDICTO is a Plug & Play predictive maintenance solution that uses measurement from the operational parameters – vibration, temperature and sound, to forecast issues and malfunctions.

Advanced Asset Management

Advanced Asset Management

PREDICTO Industrial Node measures tri-axial vibration and surface temperature of rotating equipment, such as pumps, motors, and compressors, with a sampling rate up to 4.8KHz.

PREDICTO Industrial Node measures tri-axial vibration and surface temperature of rotating equipment, such as pumps, motors, and compressors, with a frequency range up to 6.6kHz.

PREDICTO Industrial Node measures tri-axial vibration and surface temperature of rotating equipment, such as pumps, motors, and compressors, with a frequency range up to 6.6kHz.

Take

The Next Step

Booking a demo with PREDICTO is a great way to see how our predictive maintenance sensor and platform can help you reduce downtime, increase efficiency, and optimize maintenance costs. Our demo will show you how our sensor and platform work, how they can be applied to your industry and assets, and how they can provide you with real-time insights and alerts on the health and status of your assets.

Take

The Next Step

Booking a demo with PREDICTO is a great way to see how our predictive maintenance sensor and platform can help you reduce downtime, increase efficiency, and optimize maintenance costs. Our demo will show you how our sensor and platform work, how they can be applied to your industry and assets, and how they can provide you with real-time insights and alerts on the health and status of your assets.

TAKE THE NEXT STEP!

Booking a demo with Predicto is a great way to see how our predictive maintenance sensor and platform can help you reduce downtime, increase efficiency, and optimize maintenance costs. Our demo will show you how our sensor and platform work, how they can be applied to your industry and assets, and how they can provide you with real-time insights and alerts on the health and status of your assets.