START CUTTING SOONER WITH

PRE-ASSEMBLED MACHINES

At Tormach, we have a long-standing philosophy that we want to provide the most value to our customers. That’s why you have the ability to self-service, we have free technical support for as long as you own your machine, and you can take delivery of a mill, lathe, plasma table, or router via a liftgate truck. Those perks mean that there is some assembly required when you receive your machine. If you have a stand or enclosure, those will need to be assembled, or if you ordered any accessories, like an ATC, those will need to be installed, once your machine arrives.

WHY CHOOSE TORMACH PRE-ASSEMBLY?

Save Time with Factory Assembly

Skip the complexity of building your machine from scratch. Our technicians pre-assemble the base machine and select components at our facility, so you receive a machine that’s closer to ready-to-run.

Shipped with Care, Ready for Setup

Once pre-assembly is complete, we carefully package and ship your machine. When it arrives, you’ll only need to level it and complete final setup steps at your facility.

Flexible Options for Every Need

Choose full pre-assembly for most Tormach machines or a partial pre-assembly option for the PCNC 440.

HOW DOES IT WORK?

If you are a larger business, school, or simply do not have the time to commit to assembling your machine and installing accessories (time is money, after all), we offer an assembly service for a reasonable fee. Let us assemble your new machine here at Tormach, and we will build it and ship it out to you. With machine assembly, a Tormach professional installs, aligns and tests major components to the machine, allowing you to commission the machine quickly at your shop once it arrives.

Note: When ordering an assembled machine you will need to have either a loading dock or a forklift to remove the crate from the carriers truck. The Tormach Supply Chain team can provide specific information about your machine build. Some typical crate sizes and machine weights are as follows:

- 770MX Fully Loaded: 78 in. x 65 in. x 81 in. | 2000 lbs.

- 1100MX Fully Loaded: 92 in. x 73 in. x 89 in. | 2800 lbs.

Some of The Items We Can Assemble Include:

- Automatic Tool Changers (ATC)

- High-Performance Servo Motors

- High-Performance Spindles

- Coolant Systems

- Enclosures (Dependant upon shop door dimensions)

- PathPilot Operator Consoles

- Machine Stands

THE TORMACH DIFFERENCE

Tormach Pre-Assembly is designed to make your machine setup easier — not more complicated or costly. Unlike other manufacturers, we give you the flexibility to choose what fits your needs. Whether you want to hit the ground running with a fully assembled machine or prefer to handle final setup yourself, pre-assembly is an optional service that helps you get started faster, with confidence. It’s just one more way we put control back in your hands.

PRICING

Full machine assembly is available for $2,995, while a partial assembly option—exclusive to the PCNC 440—is available for $1,195. Pre-Assembly is available for new machines purchased through Tormach and includes professional assembly of the base machine and select components at our facility. The machine is then shipped to you for final leveling and installation at your location.

HOW TO REQUEST MACHINE ASSEMBLY

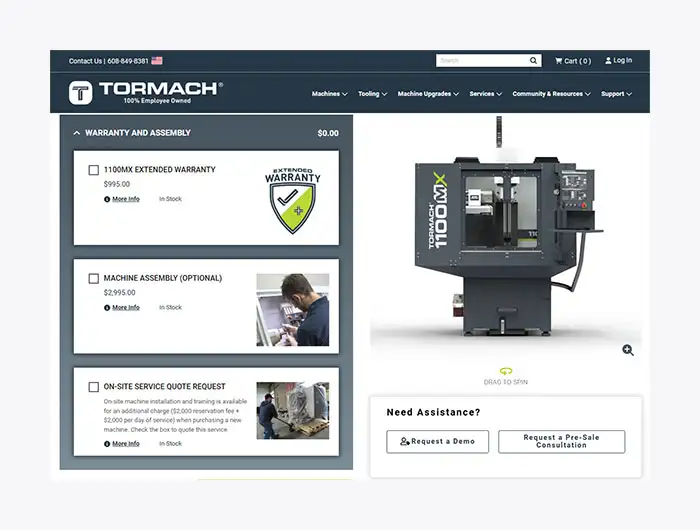

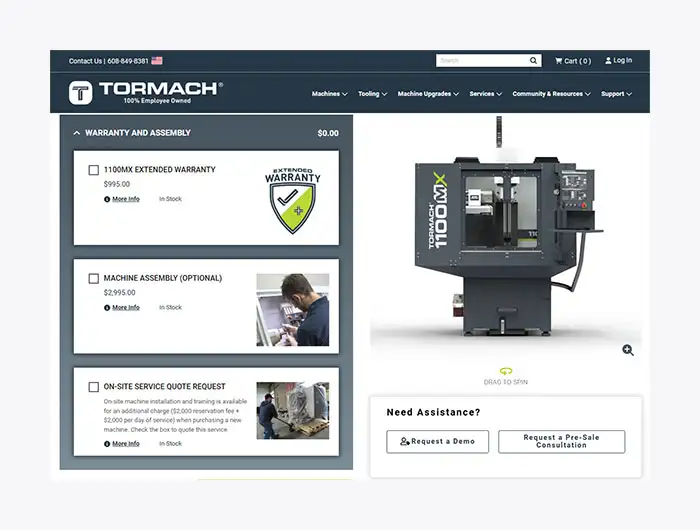

Assembly pricing depends upon machine choice, and can be found as an option in each Machine Builder Package.

When configuring your machine, select Machine Assembly in the Warranty and Assembly section. When you complete the machine build by requesting a quote or making a purchase, that Machine Assembly inquiry will go to our team, who will provide a quote for your specific assembly/training needs.

Assembly Services

At Tormach, we have a long-standing philosophy that we want to provide the most value to our customers. That’s why you have the ability to self-service, we have free technical support for as long as you own your machine, and you can take delivery of a mill, lathe, plasma table, or router via a liftgate truck. Those perks mean that there is some assembly required when you receive your machine. If you have a stand or enclosure, those will need to be assembled, or if you ordered any accessories, like an ATC, those will need to be installed, once your machine arrives.

How Does It Work?

If you are a larger business, school, or simply do not have the time to commit to assembling your machine and installing accessories (time is money, after all), we offer an assembly service for a reasonable fee. Let us assemble your new machine here at Tormach, and we will build it and ship it out to you. With machine assembly, a Tormach professional installs, aligns and tests major components to the machine, allowing you to commission the machine quickly at your shop once it arrives.

Note: When ordering an assembled machine you will need to have either a loading dock or a forklift to remove the crate from the carriers truck. The Tormach Supply Chain team can provide specific information about your machine build. Some typical crate sizes and machine weights are as follows:

- 770MX Fully Loaded: 78 in. x 65 in. x 81 in. | 2000 lbs.

- 1100MX Fully Loaded: 92 in. x 73 in. x 89 in. | 2800 lbs.

How to Request Machine Assembly

Assembly pricing depends upon machine choice, and can be found as an option in each Machine Builder Package.

When configuring your machine, select Machine Assembly in the Warranty and Assembly section. When you complete the machine build by requesting a quote or making a purchase, that Machine Assembly inquiry will go to our team, who will provide a quote for your specific assembly/training needs.