Honor the Hands That Build Moldmaking’s Future

The SPE Mold Technologies Division is calling for nominations for its 2026 Moldmaking Distinction Awards to be awarded live at PTXPO 2026.

Read MoreTrending

An Unfolding Workforce Challenge: 8 Years of Moldmaking’s Talent Crisis

A look at moldmaking’s workforce development journey, examining persistent challenges, innovative solutions and the gaps that remain after nearly a decade of focused effort.

Read MoreWhy Mold Builders Must Embrace On-Machine Deburring

Advancements in tooling and CAM make automated on-machine deburring essential, improving mold quality, repeatability and easing skilled labor shortages.

Read MoreMoldMaking Technology's Most-Viewed Content of 2025

The most popular MoldMaking Technology content according to analytics reports over the past year.

Read MoreThe Power of Thanks: Building the Future of Moldmaking Together

A bold four-day event highlights the value of strong supplier relationships and open dialogue, proving that gratitude and collaboration can help move moldmaking forward.

Read More

MANUFACTURING CONNECTED

Industry Moves Fast. We Make Sense of What's Next.

Basics

VIEW ALL2025 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2025, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreSmart Tech, Smarter Investments, Skilled Workforce

MMT's Editorial Advisory Board member Gabe English and president of Western Carolina Tool & Mold shares his top MoldMaking Technology articles over the past year and how this content has been valuable to the business.

Read MoreHow to Put AI to Work in EDM

AI streamlines EDM with dashboards, NFC integration, data extraction, wire cutter design, G-code optimization and tool setter enhancements.

Read MoreHow to Use Ultra-Precision Micro Tools, Molding and Automation to Unlock High-Volume Medical Device Miniaturization

Five key areas where a molder/mold builder applies tight-tolerance tooling and advanced molding solutions to enable high-volume production of micro-molded medical parts.

Read MoreHow to Automate Process and Design in Moldmaking

Mold builders can achieve major operational improvements by automating their digital workflows, particularly in CAD/CAM design, programming and process planning.

Read MoreMMT Chat: True Industry/Education Partnership Demands “Consistent Persistence”

High school teachers often ask, "How can I find a company willing to partner with me?" This question may seem straightforward, but establishing a genuine partnership with a local high school to address the skills gap requires ongoing commitment and consistent communication. Electroform, based in Rockford, IL, and Hononegah High School have made that commitment.

WatchVideos

VIEW ALLGiant Tooling System Enhances High-Precision, Heavy-Duty Machining

Erowa Technology introduces the Giant Tooling System (GTS), designed for robust and efficient machining of large and heavy workpieces in demanding environments.

WatchCAD/CAM Software Suite Enhances Intelligent Workflow for Tool, Moldmaking Projects

IMTS 2024: Open Mind Technologies showcases its hyperMILL CAD/CAM software with enhancements to its toolpath capabilities, overall functionality and more.

WatchCNC Platform Creates Adaptable Interface for Workholding

IMTS 2024: Features such as advanced collision protection and greater operational functionality make Heidenhain’s TNC7 CNC control platform critical for mold builders, who often face multi-surface machining.

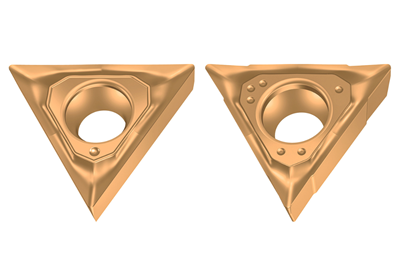

WatchTangentially Mounted Inserts Achieve Multifunctional Milling

The Kyocera MA90 milling insert series delivers high body rigidity with lower cutting forces in an effort to provide tough and reliable machining performance.

WatchHighly Wear-Resistant Thread Milling Grade Promotes Difficult Material Cutting

The Walter USA Tiger·tec Gold grade WSM37G is most effective for machining blind-hole and through-hole threads in hard steel, stainless steel, cast iron and heat-resistant super alloys.

WatchUniversity Programs Expose Next-Gen Students to Moldmaking, Plastics

NPE2024: The University of Massachusetts Lowell extends an invitation to its Alumni and Friends Reception to university alumni and industry professionals, highlights successful programs giving hands-on manufacturing experience.

Watch

Latest Issue

News

- Markus Büngers Named New Hasco CEO

- Molding Expert LLC to Debut Industry’s First VR Mold Assembly Training at PTXPO 2026

- IACMI Launches ‘Make It In America’ National Outreach Campaign

- Hoffer Plastics Expands Sales Team to Deliver Deeper Industry Expertise

- SPE's Mold Technologies Division Names 2026 Scholarships and Grants

- DMG MORI, Haimer Expand Strategic Partnership

- PCS Company to Host Mold Maintenance Open House with iD Additives, Other Brands at Michigan Headquarters

- UWM Offers Molding of Rubber, Design of Rubber Molds Course

Products

Hasco Expands Offerings, Including 3D-Printed Hot Runners

Updates include cooling systems, slide retainers, chemical working substances and online ordering, along with advances for additive manufacturing in hot runners.

Read MoreDry-Ice Pelletizer Produces 120 Pounds of High-Density Pellets Hourly

The SUR-120 runs on a standard 220-volt outlet single-phase connection.

Read MoreLSR Molding Dosing System Designed for Precision, Efficiency and Compliance

The system offers a variety of features to successfully produce high-quality silicone parts with the most economic use of material, space, working time and energy.

Read More