Products

col

Edge Devices

Wireless data acquisition

Wireless Sensors

col

col

Applications

col

col

col

Partners

Company

Resources

Enable reliable and secure IoT networks for your mining monitoring systems. Operable and reliable wireless system for your infrastructure monitoring needs:

The mining landscape is becoming increasingly complex, with transitions from surface to underground operations, the need to manage tailings dams, and heightened risks from extreme weather conditions. These challenges require geotechnical engineers and EPCM teams to deploy robust mining monitoring systems that can adapt to the evolving demands of modern mining operations.

Deploy robust and reliable wireless monitoring networks to adapt to the dynamic conditions of your project environments. Our smart mining monitoring solutions offer excelling range of network capacity to reach large distances and cope with high volumes of mining sensor data.

Implement robust and reliable mining monitoring systems that provide a secure, continuous data stream for your growing monitoring requirements. With superior range and network capacity, you can optimize your network deployment and minimize maintenance.

Deploy monitoring systems using a single-net configuration for closed, local management of mining monitoring systems or deploy multi-network configurations when centralized management is needed.

What makes Worldsensing the best option to connect your remote monitoring systems.

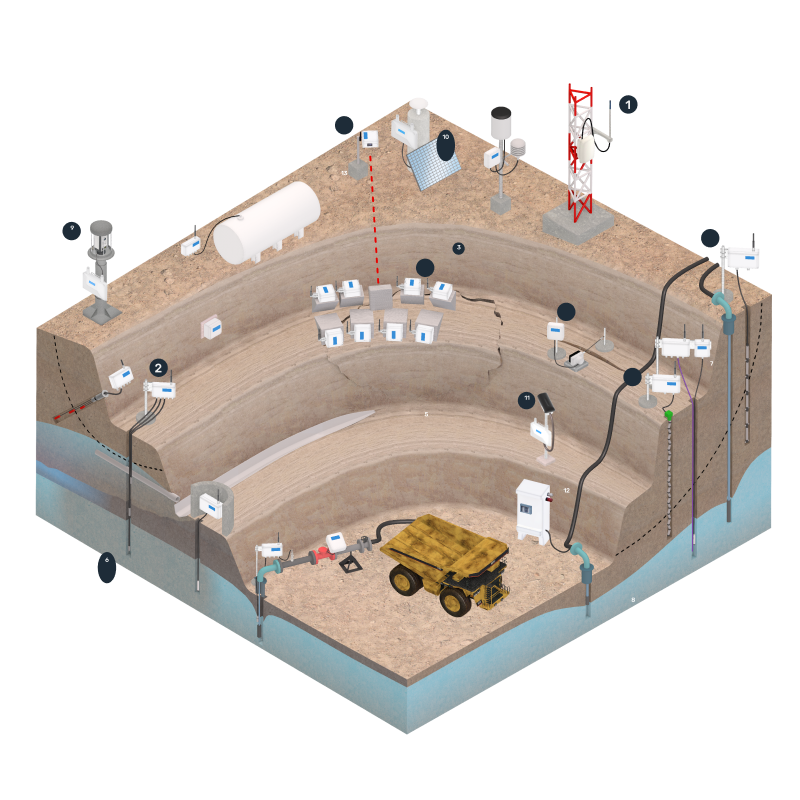

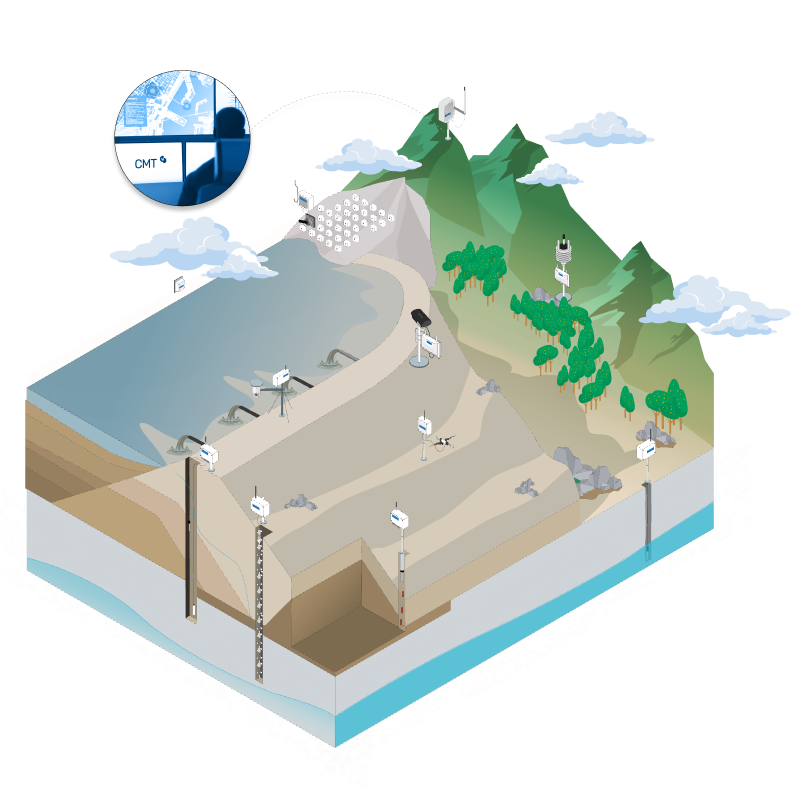

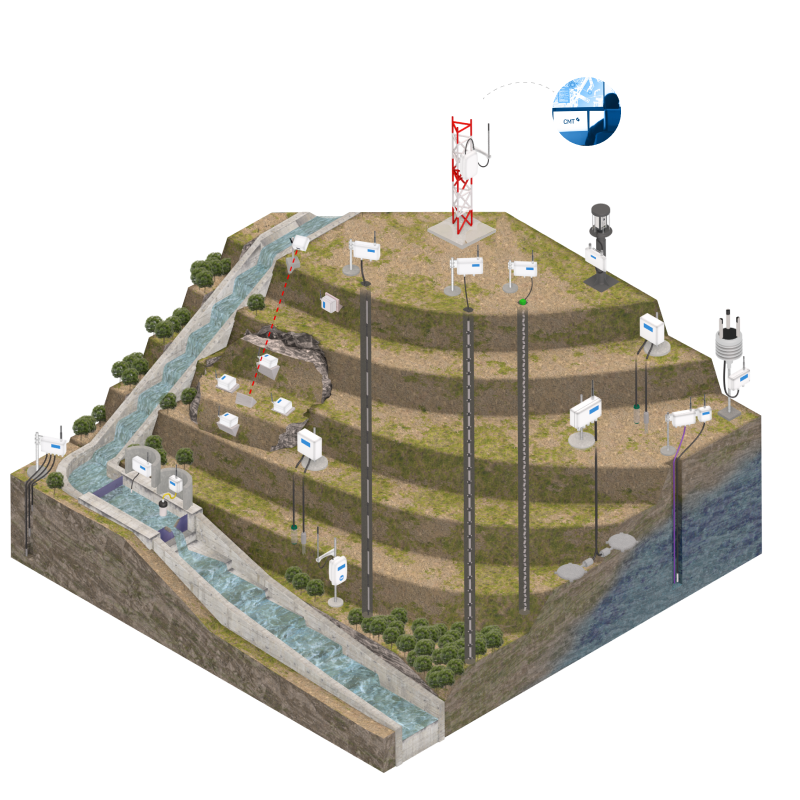

We enable connectivity in most of geotechnical, structural and environmental monitoring areas of:

Extensive compatibility with geotechnical instrumentation for surface mine monitoring: MPBX’s, IPI’s, inclinometers and others.

Deploy robust, end-to-end, real-time early warning systems to comply with new global industry standards regarding risk management for tailings (GPMI). Manage slope risks in tailings dams and monitor various geotechnical and structural parameters within a unified network.

Leverage the network capabilities of Worldsensing networks to manage all your different monitoring needs, from geotechnical and geospatial to structural and environmental.

Utilize our unique solution for extended network coverage up to 10 km underground, designed for tunnels, ground excavations and complex subterranean topologies.

We enable connectivity for transportation-related assets facilitating reliable and comprehensive mining monitoring systems.

In-place inclinometers are positioned at fixed locations in the inclinometer borehole allowing continuous monitoring. Connect Shape Arrays and IPIs and wirelessly transmit data using the Digital Data Logger or the broadband ThreadX3 for longer chains.

Up to 200 segments of Shape Array using the Digital Logger and up to 300 segments using the ThreadX3.

Leverage compatibility with all major manufacturers of multi-point extensometers (MPBX) and in-place extensometers (IPX). Connect any vibrating wire, potentiometer, or analog displacement sensors installed in the head of the extensometer to the appropriate data logger. Digital MPBXs allow for reading more points with a single digital logger and enable the connection of more than one MPBX to the node.

Detect slope movements by monitoring tension cracks across landslides using a displacement sensor compatible with Worldsensing’s Analog or Vibrating Wire data logger. For situations with large movements anticipated, wireline extensometers, draw wire sensors, or the LaserTilt90 can be suitable alternatives.

Connect piezometers and multi-point piezometers from all the major geotechnical sensor manufacturers. Use 1-channel or 5-channel Vibrating Wire data loggers to transmit data from any number of sensor configurations. Water level sensors can be connected through Analog or Digital Data Loggers.

Use cost-efficient GNSS sensors connected to a ThreadX3 to accurately monitor ground movements and land deformation in vast areas such as tailings dams, open-pit mines and their surrounding areas, regions affected by subsidence and decommissioned mines.

Complement your geotechnical monitoring with a total station connected to a ThreadX3 for accurate movement detection.

When rapid detection is necessary for real-time decision-making, use G7 Tiltmeters event detection operational mode. It offers less than 2 seconds of latency for movement detection. Paired with in-field cameras connected through Thread X3, they form a complete Early Warning System for end-to-end solution for effective risk management.

Ensure the proper functionality of anchor systems -active and passive- by monitoring in a representative sample the load throughout their lifecycle including the load tests and stressing works. Stream data wirelessly from most of the load cells based on resistive strain gauges available in the market using the Piconode analog data logger. The 5-channel Vibrating Wire and the Digital Logger can also be suitable, depending on the type of load cell.

Assess the tangential and radial stresses in shotcrete support for underground excavations with pressure cells connected to the Vibrating Wire 5-channel data logger.

Attach VW Strain Gauges to the steel arch supported by arc welding them directly to the steel arch to achieve long-term strain measurements of the structural element. Connect the gauges to the Vibrating Wire 5-channel data logger. Additionally, it is possible to embed VW Strain Gauges in the shotcrete to measure strains within the tunnel lining.

Crack meters available in the market can be readily connected to a Vibrating Wire 1-channel data logger or the Piconode to monitor movement across surface cracks.

Monitor the impact of industrial activities on surrounding infrastructure with Worldsensing’s Vibration Meter, designed to operate in compliance with industry standards for building integrity (DIN4150-3 and BS7385-2).

Compatibility with major weather transmitter manufacturers via digital interface. Monitor precipitation, air temperature and other weather parameters using a weather transmitter connected to a Digital logger or ThreadX3. Multiple configurations readily available to stream the right data to your information systems.

Monitor the impact of vibrations created by industrial activities on people’s comfort with Worldsensing’s Vibration Meter, designed to operate in compliance with industry standards (ISO 2631-2).

Discover the different product families that compose Worldsensing's IoT connectivity solutions for remote monitoring.

Long-range, low-power devices that allow you to wirelessly transmit data from sensors to your information systems. Use our devices to transmit data from the widest catalog of analog, digital and vibrating wire sensors.

Choose your network and enable your communications with Worldsensing’s broadband and narrowband connectivity portfolio of gateways and repeaters.

Centralize your network, device and data management operations under a single platform using CMT. Whether you are deploying private networks or cloud-based deployments, CMT has a management software solution for your project.

Discover how Worldsensing has made a positive impact, providing reliable solutions and exceptional support.

An important point in the project was the concrete anti-vandalism protection used to guarantee the safety of the equipment. Even with this protection, the system managed to transmit to the gateway more than 2 kilometers away.Read success story

Rodrigo Raposo

Geotechnical Engineer, D.Sc and Consultant, RD&I, 3Geo Tecnologia

It’s 100% satisfaction. Our client keeps coming back and asking for more digital nodes. The return on investment is easily less than a year for this.Read success story

Adam Dulmage

Businesss Development Executive, Mining sector, GEO-Instruments Canada (formerly GKM Consultants)

We've had a good relationship with Worldsensing for a number of years and we are one of their early adopters. We've really seen the value in a wireless solution. The Modbus protocol implementation on the gateway allows for seamless integration to existing communication infrastructure. This also isolates access to the data and reduces the impact of network outage in the area.Read success story

Ben Scott

Technical Manager, Geomotion

One of the Worldsensing gateways that we first installed has kept on monitoring for years, without any work done on it. I haven’t had to check that gateway since I installed it. This kind of reliability is one of the biggest advantages of this system.Read success story

Rodrigo Vicencio

Chief Operating Officer, Geosinergia

The adoption of Worldsensing technology eliminates the need for cabling, reduces manual monitoring and allows significant savings up to 50% on the acquisition of materials and infrastructure and up to 50% on installation as opposed to other monitoring platforms we have installed in the first excavation phase.Read success story

Alexandre Cosentino

Mining Engineer, GEO-Instruments Canada (formerly GKM Consultants)

In the past, we would have done it with cables. It would have been a lot of work for the construction company. It’s not really competitive anymore to use cable systems in geotechnical projects.Read success story

Daniel Naterop

Project Manager, Huggenberger

The Worldsensing repeater has demonstrated very good capabilities in this demo. You could have the greatest instrumentation in the world, but at the end of the day if you don’t get that data, you can’t make timely decisions and you have wasted company money.Read success story

Peter Lausch

Chief Operating Officer, Mine Design Technologies (MDT)

Worldsensing equipment provides reliable information which can be accessed easily by people of various skills working in the mine or remotely over the network. GKM has provided effective support for the products, allowing the focus at site to remain on the information being gathered rather than on troubleshooting or maintenance of the devices.Read success story

Darren Neely

Senior Rock Mechanics Engineer, Vascoy Potash, Nutrien

Worldsensing is very easy to use. The most important benefit is the wireless connection, in combination with the long range and the low-power consumption.

Erdmann Jacobeit

Terra Vermessungen

Remote monitoring and advanced data assessment play a vital role in managing ageing tunnel assets, bridging plausibility gaps, and enabling data-driven decision-making.Read success story

Phil Cutter

Senior Market Lead, Principal Engineer, Rockfield Technologies Australia