Welcome

The Robotics Innovation Center (RIC) belongs to the Bremen location of the German Research Center for Artificial Intelligence (DFKI GmbH). Headed by Prof. Dr. Dr. h.c. Frank Kirchner, here scientists develop robot systems to be used for complex tasks on land, under water, in the air, and in space. The RIC closely cooperates with the Robotics Group at the University of Bremen.

The DFKI is the leading German research centre in relation to innovative software technology based on methods of Artificial Intelligence. It comprises sites in Kaiserslautern, Saarbrücken, Bremen and Lower Saxony, as well as laboratories in Berlin and Darmstadt, and branch offices in Lübeck and Trier.

For further information please visit this page.

Latest Projects

Latest Videos

ROMATRIS: Closing event at the THW training ground in Wesel

THW and DFKI develop innovative robot system for disaster relief operations. After four years of intensive research, the ROMATRIS project has been successfully completed. The German Federal Agency for Technical Relief (THW) and the German Research Center for Artificial Intelligence (DFKI) have developed a novel robot system for material transport. The easy-to-use mobile helper can relieve the burden on emergency services and make operations safer.

MARIOW: AI-powered underwater welding robot for maritime maintenance

In the MARIOW project, an innovative underwater welding robot has been developed that can perform semi-autonomous welding tasks on maritime infrastructure.

The robot features a robotic arm developed at the DFKI. It can operate at depths of up to 6,000 meters, offers six degrees of freedom, and has a reach of two meters.

The video shows the final phase of the project at DFKI in Bremen, including underwater testing of the robot, demonstration of the flux-cored arc welding process, and AI-based seam detection.

RoLand: Automated fruit harvesting with AI – SHIVAA robot put to the test at Glantz strawberry farm

The aim of the RoLand project is to develop a semi-autonomous, mobile harvesting system that can reliably pick fruit in open fields. Unlike previous solutions, which are mainly used in greenhouses, the robot is specially designed to cope with the challenges of real-world environmental conditions such as changing weather or uneven terrain. Due to its versatility and cost-efficiency, the system is also of interest to smaller farms. In addition, the work output can be flexibly scaled by operating several compact units in parallel.

The video shows the first public field test of the SHIVAA robot at the Glantz strawberry farm in August 2025. In it, the project partners explain the goals and advantages of the system.

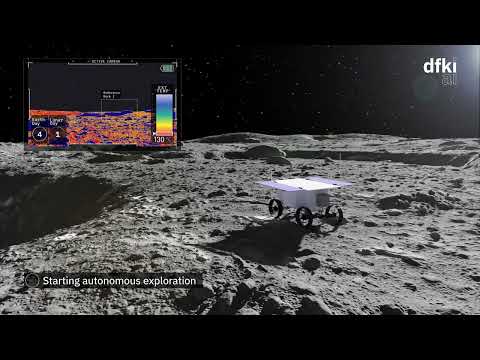

SAMLER-KI: Surviving Lunar Nights - AI-Powered Micro Rover for Future Moon Missions

Robotic systems will play a key role in future lunar missions, and a great deal of research is currently being conducted in this area. The SAMLER-AI project is also conducting research in this area.. The project focuses on the conceptual design of a semi-autonomous micro rover that is capable of surviving lunar nights while remaining within the size class of a micro rover. During development, conditions on the Moon such as dust exposure, radiation, and the vacuum of space are taken into account, along with the 14-Earth-day duration of a lunar night.

For a reference mission, the surroundings of the Reiner Gamma region were selected. This example mission is planned to start on 16 March 2030 at 21:00:00 Barycentric Dynamical Time (TDB) and will last for two lunar days, concluding on 27 April 2030 at 13:00:00 TDB. The highlight of the mission will be the rover surviving the lunar night, allowing it to continue its journey into the second lunar day.

The animation shows the approach developed so far by DFKI and FH Aachen.

MikroBeM: In Airbus A310 Zero G

Parabolic flight with exoskeleton: DFKI and the University of Duisburg-Essen are researching innovative space training in zero gravity

Persim: Autonomous navigation on steep slope of a crater

The autonomous navigation of Coyote 3 is presented while a steep slope is traversed. The map below on the right shows the traversable areas as green, and the obstacles in red. The planned path to be followed is also displayed in the visualization.