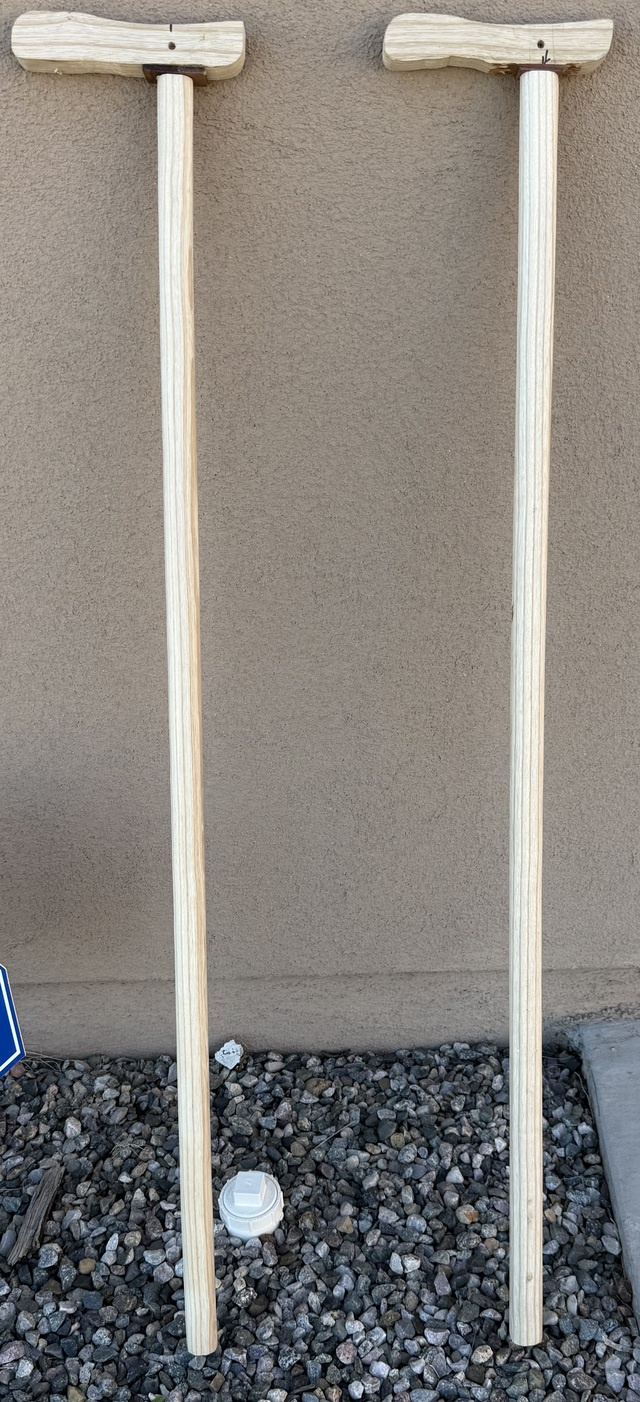

After section 11, I got asked by some woodworking friends about how one grips a cane, and how the physics of the joint work. Specifically:

How does one grab that, hand behind the shaft or does one wrap the index finger around the front portion?

And:

I've never required the need for a cane, but my two cents for what it's worth: regarding the question asked by Mr. Splinter, it would seem to me that the cane should be held with the hand centered over the shaft. This would reduce or eliminate the handle being pushed down on one side, thus this lever action might loosen the joint, or elongate the mortise. What do you think?

I answered as follows:

On my cane, I grip it as I described earlier, with my index finger either pointing down the shaft, or slightly ahead of it. One gal I know holds her cane “backwards” so the heel of her hand is directly over the shaft. It works for her, but I find it hugely uncomfortable.

As for torque on the joint, yes, that’s a possibility, but I’m drawboring the joint, so the shoulder around the tenon should be tight against the cheeks of the mortise, and I’ll stick wedges around the tenon to take up any looseness in the mortise before I drive in the drawbore peg. That’s the same technique I used on mine, and with almost a decade of on and off use, plus moving from MN to NM and having all the wood shrink from the dry, the joint is still rock solid.

I would be a little concerned about the joint if he were going to take the cane to somewhere soupy like Houston or Nawlins after it was built here in the desert, but the monsoon this summer has kept our dewpoints above the mid-40s all summer, so the wood is not as bone-dry as usual.

The only way I can think of to make the joint more solid would be to boil the joint, but that’s a one-and-done technique, and I don’t trust myself to get it perfect on the first try. I will be boiling the (live oak) trenail that will be holding the joint together (along with some glue), and as that dries, it should try to straighten out and pull the joint even more tightly together.

But yeah, in a perfect world, (along with the spherical cows and frictionless floors from my freshman physics course) the weight from your arm would be in a mostly straight line down the shaft. Then again, I’m overbuilding this fairly seriously, and it’s not as if it’s a completely original design.

Discuss...

Reply to this in the fediverse: @davepolaschek@writing.exchange