info@truecadd.com

Reverse Engineering for Seamless Product Optimization & Replication

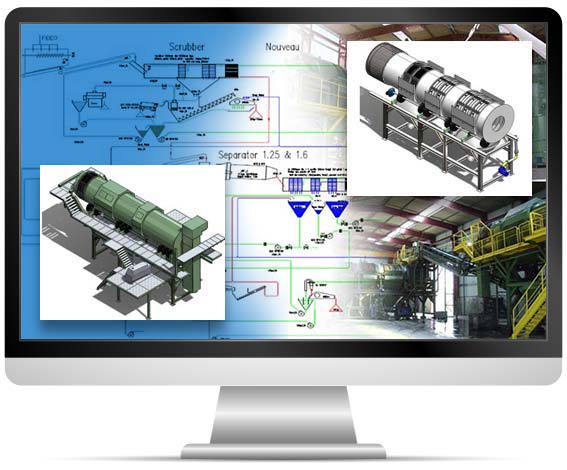

Our company specializes in reverse engineering services through manual interpretation of physical measurements, sketches and existing documents to produce production-ready 3D parametric models, surfaced designs and detailed manufacturing drawings using SolidWorks and Autodesk Inventor.

Our wide range of reverse engineering services provides total life-cycle support for both onsite and offshore projects. Every client’s project is customized to meet their exact requirements, as we believe that every project is different.

Our Core Reverse Engineering Services Offerings

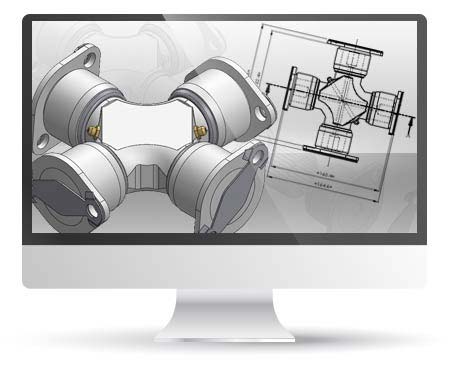

3D CAD Modeling from Physical Parts

- Manual data extraction (no 3D scanning required)

- Create fully parametric models, including surfacing and feature-based geometry

- Ideal for reverse engineering mechanical parts with missing or outdated CAD

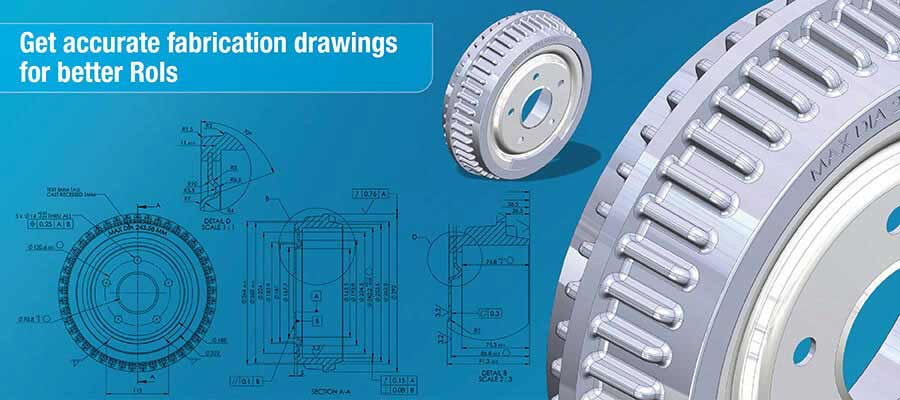

2D Drawings from Physical Components

- Develop precise 2D manufacturing drawings from actual components

- Include tolerances, GD&T, material specifications, and annotations

2D to 3D CAD Conversion

- Upgrade legacy 2D blueprints into fully functional 3D CAD models

- Support mechanical part modeling, maintaining design intent and critical features

- Deliverables include native and neutral formats like .SLDPRT, .STEP, and .IGES

Reverse Engineering for Product Redesign

- Reconstruct old parts and optimize with new design improvements

- Enable parametric modeling for easy future modifications and revisions

- Support redesign for better performance, fit, and manufacturability

Assembly Modeling Without Scanning

- Recreate entire assemblies from physical part measurements or photos

- Include exploded views, motion studies, and fitment checks using SolidWorks or Inventor

- Ideal for mechanical equipment restoration and part interoperability

Legacy Data Rebuilds

- Rebuild CAD data for obsolete or unsupported components

- Generate up-to-date manufacturing drawings and assemblies for spare part production or compliance

- Compatible with both Inventor and SolidWorks-based workflows

We do not offer 3D scanning services. Instead, we work effectively with:

What our Clients say

Founder & Owner, Technology Consultancy for AEC industry – USA

Why choose TrueCADD for your Reverse Engineering Needs

Precision Surface Modeling

The process requires accurate modeling of performance surfaces to achieve product design optimization.

Cost-Efficient Prototyping

The development process needs digital prototypes to achieve cost-efficient results.

Legacy Part Integration

The design of new parts needs to be done in a way that they can be integrated with existing components.

Competitive Benchmarking Insights

The analysis of competitors helps businesses develop better product strategies.

Modernized Manufacturing Processes

Modernize manufacturing to improve efficiency and innovation.

Accurate Design Capture

Get CAD data that maintains the exact design intent of the original model.

Quality & Durability Optimization

The product quality needs improvement to achieve its complete potential for durability and performance.

Defect-Free Redesigning

The design process should include modifications to parts which focus on defect elimination and reliability improvement.

Benefits of Outsourcing Reverse Engineering Services

Outsourcing reverse engineering services enables organizations to reconstruct engineering data through a distinct method of refinement and restoration.

- Preserving Legacy Designs: Through reverse engineering techniques we can recover lost original blueprints which protects vital designs from disappearing into historical obscurity.

- Cost-Effective Solutions: The method eliminates the requirement for costly 3D scanning tools which results in cost reduction without affecting precision levels.

- Enhanced Customization: Engineers use existing designs to create modifications which enhance operational performance and system functionality.

- Failure Analysis & Improvement: Engineers achieve better product designs through component breakdown analysis which results in longer-lasting products with improved functionality.

- Optimized Manufacturing: Organizations can optimize their manufacturing through reverse engineering which helps them decrease waste production while enhancing operational efficiency.

- Regulatory Compliance: Ensures older systems meet modern safety and environmental standards through careful analysis and modifications.

- Competitive Edge: Studying competitor designs enables companies to improve their products which results in market leadership.

- Digital Transformation: The process transforms physical elements into digital models which serve as references for future use and enable simulation and predictive maintenance operations.

Top FAQ’s on Reverse Engineering Services

Reverse engineering is the process of analyzing an existing product to recreate or improve it. The technology provides essential benefits for design recovery, performance enhancement, and advancements in manufacturing processes.

Not necessarily! 3D scanning provides useful results yet reverse engineering professionals can achieve their goals through traditional measurement methods and CAD modeling and expert analysis.

Absolutely! The process of reverse engineering enables you to optimize your designs while removing flaws and improving performance which results in optimal product operation.

Yes, as long as it respects intellectual property laws. The process of reverse engineering serves multiple purposes including maintenance work and innovation development and compatibility enhancement while staying within legal boundaries of patents and copyrights.

The project duration will be determined by how intricate the final product turns out to be. Design completion time depends on complexity because simple components need only a few days but complex designs require weeks of detailed analysis and modeling.

Yes! The process of reverse engineering enables the reconstruction of outdated components which maintain modern system compatibility to extend equipment operational duration.

Our Customers

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.