Lead your factory's digital transformation with a unified industrial data hub.

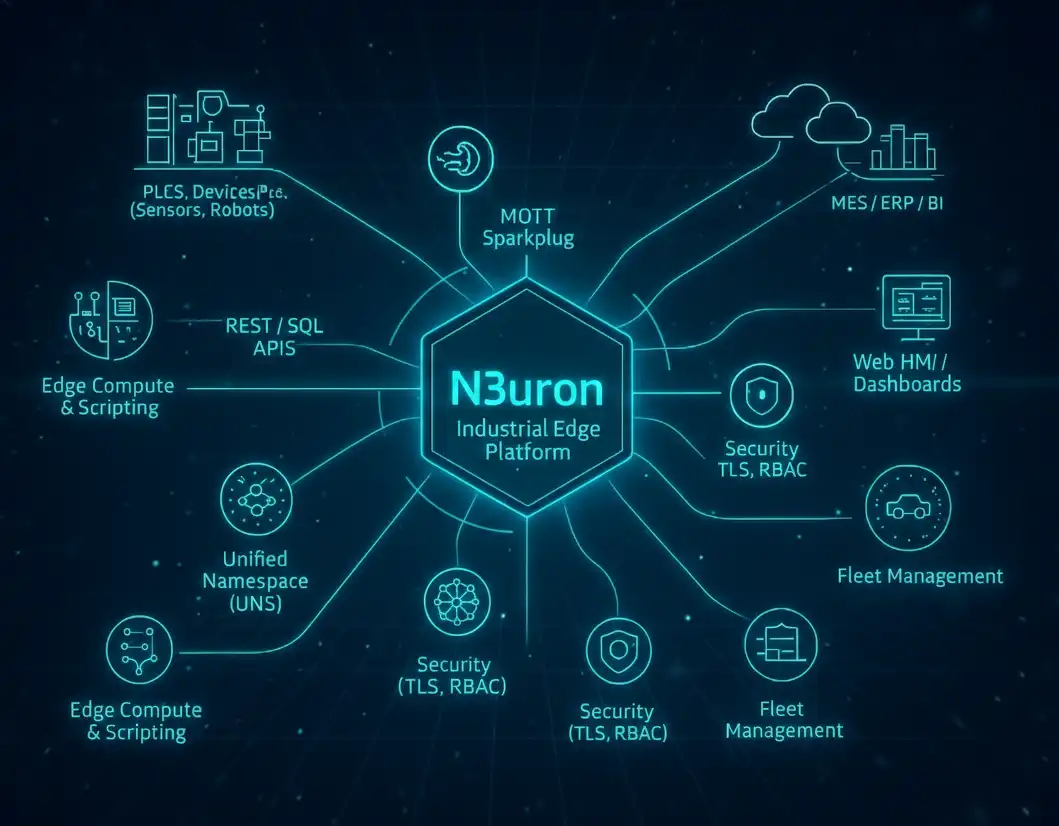

N3uron is a modular, edge-native industrial platform that streamlines the flow of data between plant-floor systems and business applications – whether on-premise or in the cloud. It provides an out-of-the-box solution for data standardization, normalization, and contextualization, enabling seamless integration between OT and IT systems with efficient information management and unparalleled scalability and security.

Countries

Installations

Tags Per License

RAM Required

N3uron's edge-first architecture and rich library of plug-in modules make it easy to connect any device or system, convert disparate protocols, and funnel actionable data to engineers, managers, and cloud analytics in seconds. Built for performance, scale, and security, N3uron accelerates Industry 4.0 initiatives – from integrating legacy PLCs to deploying enterprise-wide Unified Namespace data models – all with minimal configuration and IT overhead.

By aggregating and modeling all your operational data at the edge, N3uron empowers operations teams to analyze data in real time.

Bridge OT and IT seamlessly. N3uron acts as a central data hub that normalizes and contextualizes information from legacy PLCs, SCADA systems, sensors, and enterprise apps into a single source of truth. Using open standards like MQTT Sparkplug, it enables a Unified Namespace architecture – providing all departments real-time access to consistent, context-rich plant data. This OT/IT convergence eliminates data silos and accelerates digital transformation.

Process data at the source for agility. N3uron's edge computing design delivers distributed intelligence by crunching data right at the production site, reducing unnecessary data traffic, latency, and cloud dependence. Large volumes of sensor and machine data are filtered, computed, and stored locally (with historian and store-and-forward buffering), ensuring real-time responsiveness and resilience even with intermittent connectivity. This minimizes bandwidth use and cloud costs while maximizing speed and reliability at remote plants.

Build exactly what you need. N3uron is fully modular – you can start small and stack additional functionality as your project grows, without downtime. Each module adds targeted capabilities (e.g. protocol drivers, analytics, visualization) to the platform. Licensing is unlimited: once a module is licensed, you can connect unlimited tags, devices, and clients with no extra fees (only constrained by hardware). This ensures massive scalability – from a single edge device to thousands of nodes – while remaining cost-efficient and future-proof.

Connect anything to everything. Out-of-the-box modules support dozens of industrial protocols and standards, allowing you to interface with virtually any OT device or IT system. N3uron speaks OPC UA/DA, Modbus, BACnet, DNP3, Siemens, SNMP, MQTT (Sparkplug), REST, SQL databases, and more. This extensive protocol library means you can easily collect data from legacy equipment, publish to MQTT brokers or cloud services, and expose information to higher-level applications via open APIs – all in one platform. By normalizing data across heterogeneous sources, N3uron simplifies integration and enables true interoperability across your enterprise.

Seamlessly link plant-floor data with IT systems. N3uron creates secure bidirectional data pipelines between operational technology and information technology environments. It can feed real-time production data to ERP, MES, analytics, or AI systems and send instructions back to the shop floor. For example, N3uron's Sparkplug MQTT support lets it serve as the contextual bridge to central SCADA platforms like Ignition, implementing a Unified Namespace for all assets and tags. At the same time, data can be forwarded to enterprise historians (OSIsoft PI, InfluxDB, TimescaleDB) or cloud IoT hubs (Azure, AWS, Google Cloud) thanks to built-in connectors. This IT/OT convergence enables end-to-end visibility and control, empowering both engineers and IT analysts with unified, high-quality data.

Industrial-strength speed and uptime. N3uron is proven in demanding production environments – handling tens of thousands of device connections and data points per site with sub-second performance. Its distributed architecture supports redundant, high-availability deployments: you can run multiple mirrored N3uron nodes with automatic failover to ensure 24/7 continuous data flow. A built-in Store & Forward mechanism guarantees no data loss during network disruptions, buffering data locally until reconnection. Whether you are monitoring a single asset or an enterprise fleet, N3uron scales horizontally and vertically to meet your throughput needs with rock-solid stability.

Protect data at every level. Security is engineered into N3uron's core. All communications can be encrypted with TLS, using advanced security protocols to safeguard data in transit. Role-based access and digital certificates ensure trusted authentication between nodes and clients. N3uron's architecture is firewall-friendly – it uses outbound connections and avoids requiring open inbound ports or public IPs, making deployment in secure industrial networks easier. By adhering to IT best practices (HTTPS, SSL, encryption standards) and industry standards (Sparkplug compliance, ISO protocols), N3uron provides peace of mind that your OT data pipeline is protected against cyber threats.

Get started in minutes, not months. N3uron's intuitive web-based interface and reusable templates help teams configure data connections and models quickly. Its lightweight footprint (<500 MB RAM required) means you can install it on almost any hardware – from a Raspberry Pi at the edge to a server in the data center. N3uron runs on both Windows and Linux (including legacy versions and ARM devices), so existing PCs or industrial PCs can be repurposed with ease. Engineers report fast deployment and easy maintenance thanks to N3uron's stability and flexibility. In short, you can roll out scalable IIoT solutions without heavy engineering effort or specialized hardware.

N3uron's architecture combines powerful industrial connectivity with modern IT-friendly features, providing a comprehensive data operations platform.

Choose from a wide range of N3uron modules to tailor the platform to your needs – from Data Acquisition modules (drivers for PLCs, energy meters, DCS, etc.) to Edge Computing modules (local logic, analytics, visualization) and Data Delivery modules (cloud connectors, APIs, historians). You only install the modules you need, keeping the system lean. New modules are continuously added, ensuring you can extend into future use cases without re-architecting.

N3uron's licensing is not tied to tag counts or device limits – one module license covers unlimited data points, users, and connections. This removes artificial scalability barriers. You can start by connecting a handful of machines and confidently grow to tens of thousands of signals across multiple sites, without worrying about escalating software costs or re-licensing.

Install N3uron on virtually any industrial device or server. It supports Windows (XP, 7, 10, Server editions) and mainstream Linux distros (Ubuntu, Red Hat, Debian, etc.), as well as ARM-based devices like Raspberry Pi. This flexibility means you can run N3uron on existing IPCs, edge gateways, or even small IIoT devices at remote sites. The platform's lightweight design ensures minimal hardware requirements and no performance penalty even on resource-constrained devices.

N3uron includes an optional web-based HMI/SCADA component for creating dashboards and control interfaces accessible from any browser. This enables users to build custom visualization solutions on top of the unified data platform, without needing separate SCADA software. Real-time data from the Unified Namespace can be visualized and even controlled securely via N3uron's web client, facilitating remote operations and centralized monitoring.

The platform makes cloud integration plug-and-play. N3uron can connect to any standard MQTT broker or major cloud IoT platform (Azure IoT Hub, AWS IoT Core, Google Cloud IoT) with just configuration. Its MQTT modules implement Sparkplug B for structured data, including unlimited store-and-forward to guarantee delivery. Beyond MQTT, N3uron can push data to REST APIs, SQL databases, or message queues, enabling straightforward integration with enterprise applications like MES, ERP, or analytics dashboards. This cloud/IT connectivity is achieved without coding, using configuration-driven modules.

To ensure data integrity, N3uron provides a high-performance time-series historian and store-and-forward buffer at the edge. Even if network links go down or cloud endpoints are unreachable, N3uron will cache data locally and automatically forward it when communications are restored. This built-in historian can be used for local trending and short-term analysis, and it supports standard query interfaces for external analytic tools. You can also interface N3uron with long-term historians like OSIsoft PI or open-source TSDBs for extended storage.

All user actions and system events in N3uron are recorded via an Audit Trail module that meets regulatory requirements (useful in GMP/FDA environments). Every tag change, configuration edit, and user login can be logged. This fosters accountability and makes it easier to troubleshoot or validate changes in a production environment. Combined with role-based security, auditing helps maintain a secure and compliant data infrastructure.

For deployments with many distributed nodes (e.g. dozens of plants or remote sites), N3uron offers a Fleet Manager solution (integrated or add-on) that allows centralized configuration, software updates, and health monitoring across all N3uron instances. This greatly simplifies management at scale – administrators can roll out new modules or settings to hundreds of edge nodes from a single interface, ensuring consistency and reducing on-site visits.

Leading organizations in manufacturing and process industries use N3uron to power their digital transformation initiatives.

Green Data Center

Green (a major data center operator) replaced a rigid SCADA system with N3uron to integrate dozens of disparate OT devices and protocols into a unified data model. N3uron's modular platform allowed Green to bridge legacy OT interfaces with IT systems, normalizing all telemetry and implementing a unified namespace for their data center assets. The result was a scalable, high-availability monitoring platform spanning 2000+ devices per site and 8 redundant N3uron nodes, drastically improving agility and reducing integration lead times.

Sonnedix & Arevon

N3uron is trusted by renewable energy producers to standardize and centralize data from solar farms, wind turbines, and battery storage systems. Sonnedix uses N3uron to aggregate and contextualize data across its global solar PV plant portfolio, providing a unified view of performance and enabling predictive maintenance across many sites. Arevon, a leader in utility-scale solar and energy storage, achieved robust, scalable BESS (Battery Energy Storage System) performance monitoring with N3uron's MQTT and historian modules, ensuring critical KPIs from inverters and battery controllers are collected and sent to cloud analytics reliably.

Automotive Manufacturing

In manufacturing environments, N3uron often serves as the data integration layer for MES/ERP and IIoT analytics. For example, an automotive parts plant can use N3uron to connect all its PLCs and machine controllers (via OPC UA and Siemens drivers) into a common model. Real-time production metrics are then fed into a cloud analytics platform and a Power BI dashboard for management, while N3uron's web HMI provides operators a live digital twin of the line. One case saw Gemmo S.p.A., an industrial contractor, create a fully integrated Energy Management System by deploying N3uron to pull energy meter data, control signals, and facility conditions into one system, enabling holistic monitoring and optimization of energy usage.

RIC Energy Solar Plant

N3uron excels at IoT retrofits in brownfield facilities. Its extensive protocol support and Custom Client module mean that even proprietary or obsolete devices can be integrated. A notable project by RIC Energy involved retrofitting a large solar plant's SCADA: N3uron was installed to interface with existing controllers and sensors (some using older protocols) and publish their data using MQTT Sparkplug to a modern SCADA/MES. This approach extended the life of legacy assets by bridging them into a modern architecture without expensive hardware replacements. N3uron's flexibility and store-and-forward also ensured that during the transition, no data was lost and downtime was minimized.

N3uron is a battle-tested platform with a growing global footprint in the industrial world.

Deployed in 60+ countries and thousands of installations, N3uron drives data in industries from energy and utilities to chemicals and food & beverage.

A wide range of organizations trust N3uron for their mission-critical operations. Notable users include renewable energy giants, pharmaceutical and manufacturing companies, utilities and infrastructure providers.

Contributing member with full Sparkplug compatibility

Member for energy industry interoperability

Listed as AWS Industrial Software partner

Collaboration for edge AI orchestration

Partnership for rugged edge devices

N3uron's commitment to security and quality is reflected in its adherence to industry standards. The platform undergoes regular updates with security enhancements and supports compliance features.

Ready to unlock the full potential of your industrial data? N3uron's Industrial Edge Platform offers a proven path to connect, visualize, and capitalize on real-time information from your machines and processes.

Whether you are an automation engineer looking to eliminate integration headaches, a plant manager aiming to reduce downtime, or an IT professional enabling Industry 4.0 initiatives, N3uron provides the tools to succeed.