Connect any industrial system without the need to code- drag, drop, and deploy.

Protocol Plug-ins

Installations

Lines of Code

OPC Router empowers teams across the organization to build industrial integrations without coding expertise.

Quickly build complex integration projects without custom programming. OPC Router's visual workflow designer lets you connect PLCs, SCADA, databases, and cloud systems in minutes instead of weeks, dramatically reducing project timelines and costs.

Enable Industry 4.0 and IIoT initiatives by seamlessly connecting legacy OT systems with modern IT infrastructure. Bridge the gap between brownfield and greenfield installations to create integrated, data-driven operations.

Automate data flows between production systems, MES, and ERP without relying on IT resources. Gain real-time visibility across all manufacturing systems and respond faster to changing production requirements.

Standardize on one flexible middleware platform for all industrial connectivity needs. Reduce the complexity of point-to-point integrations and maintain centralized control over data routing.

Everything you need to connect, transform, and route industrial data across your enterprise.

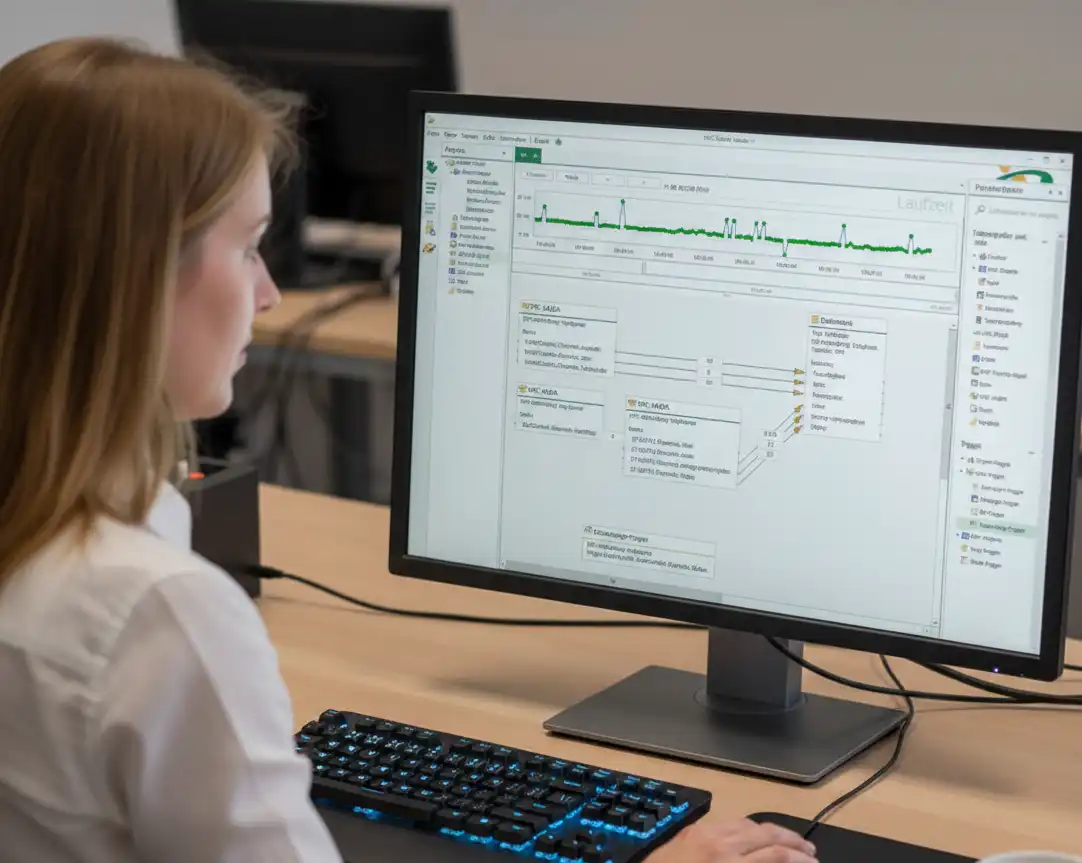

No programming knowledge required. OPC Router uses an intuitive graphical interface where you simply drag connections, protocols, and data transformations onto a canvas. Define complex data routing workflows visually - what you see is what you get. This approach means engineers can build and modify integrations on their own without waiting for developers or writing a single line of code.

Connect virtually any industrial system with OPC Router's extensive plug-in library. Includes OPC UA and OPC DA clients and servers, MQTT (including Sparkplug B), SQL databases, REST APIs, CSV/Excel files, email, FTP, SAP, and many more. New plug-ins are continuously added, ensuring you can integrate the latest industrial technologies as they emerge.

OPC Router runs as a high-performance service that processes data changes in real-time. Set up event triggers based on data changes, timers, file system events, or external signals. For example, automatically write production data to SQL when a batch completes, send alerts via email when values exceed thresholds, or trigger cloud uploads on schedule - all without manual intervention.

More than just routing - transform and process data on the fly. OPC Router includes built-in functions for mathematical calculations, string manipulation, conditional logic (if/then), data aggregation, and filtering. Create custom business logic visually to ensure the right data reaches the right destination in the right format.

Built for mission-critical operations with encrypted communications, role-based access control, and secure credential management. OPC Router supports redundant configurations and automatic failover to ensure continuous operation.

Seamlessly bridge your plant floor to the cloud. OPC Router supports all major cloud platforms (Azure, AWS, Google Cloud) via REST APIs, MQTT, and native connectors. Enable cloud-based analytics, remote monitoring, and enterprise-wide data sharing while maintaining local control and security of your OT network.

Reduce integration project time by up to 80% compared to custom development. OPC Router's pre-built plug-ins and visual configuration mean you can prototype solutions in minutes and deploy production systems in days. Lower total cost of ownership through reduced development, maintenance, and training costs.

Start small with basic connections and expand as needed. OPC Router's plug-in architecture means you only license the modules you need. Scale from simple point-to-point connections to enterprise-wide data routing across multiple sites. Projects are portable and reusable - create template workflows that can be deployed across multiple production lines.

OPC Router's drag-and-drop interface makes complex integrations simple. Connect protocols, add logic, and transform data - all without writing a single line of code.

See how OPC Router connects your systems together

OPC UA Server

SQL Database

Real-time data logging

RFID Readers

Azure IoT Hub

Cloud data streaming

CSV Files

OPC UA Server

Recipe management

SCADA System

Email/SMS

Event notifications

REST API

SQL + MQTT

Multi-destination routing

PLC Tags

SAP

ERP integration

From simple data logging to complex multi-system orchestration

Automatically transfer production data from PLCs and SCADA systems to SQL databases or historians. OPC Router reads real-time values via OPC UA/DA or MQTT, transforms the data as needed, and writes to database tables on triggers (e.g., every batch end, shift change, or data change). Eliminate manual data entry and ensure your MES/ERP systems always have current production information.

Example: Write machine status, cycle counts, and quality metrics to SQL Server every 5 minutes for real-time production dashboards.

Stream plant floor data to cloud platforms for analytics, AI/ML, and remote monitoring. Use OPC Router to read from OT systems and publish to Azure IoT Hub, AWS IoT Core, or third-party MQTT brokers using Sparkplug B. Implement buffering and store-and-forward to handle network outages gracefully. Enable digital twin applications and predictive maintenance without exposing your control network.

Example: Send sensor data from production equipment to Azure for predictive analytics while maintaining air-gapped security on the factory floor.

Set up intelligent alerting based on process conditions. OPC Router monitors live data and triggers email, SMS, or system notifications when thresholds are exceeded or events occur. Combine multiple conditions with logic to reduce false alarms. Include relevant data, timestamps, and context in notifications to help teams respond quickly.

Example: Send email alerts to maintenance when equipment vibration exceeds safe levels, including current readings and historical trends.

Automate import/export of production data via files. Watch folders for incoming CSV/Excel files and automatically process them into databases or OPC servers. Export data to CSV/JSON files on schedule or events for sharing with third-party systems. Ideal for batch record generation, shift reports, and integration with systems that don't have APIs.

Example: Automatically import recipe files from ERP, validate contents, and download to PLC recipe tables - all triggered by file arrival.

Bridge the gap between plant floor and enterprise business systems. OPC Router connects SCADA/PLC data with SAP, Oracle, or other ERP platforms via REST APIs, web services, or database connections. Enable real-time production tracking, automated work order updates, and bidirectional material tracking without custom middleware development.

Example: Update SAP with real-time production counts and material consumption, while downloading work orders and recipes to the plant floor.

Consolidate data from distributed production facilities into central systems. Deploy OPC Router instances at each site to collect and standardize local data, then route to corporate historians, databases, or cloud platforms. Create unified dashboards and reports across all locations while respecting local network security policies.

Example: Aggregate OEE data from 10 manufacturing plants into a central Power BI dashboard for corporate visibility.

Act as a universal protocol converter between incompatible systems. Convert between OPC UA, OPC DA MQTT, or even REST API. OPC Router handles the translation seamlessly, allowing modern and legacy systems to communicate. Perfect for brownfield upgrades where replacing existing infrastructure isn't feasible.

Example: Enable an OPC UA-only cloud application to read data from legacy OPC DA devices via OPC Router protocol conversion.

Coordinate data flows between multiple production systems and lines. Use OPC Router to synchronize recipe changes across parallel lines, share quality data between stations, or trigger downstream processes based on upstream events. Implement complex production workflows that span multiple PLCs and systems.

Example: When Line A completes a batch, automatically trigger Line B to start processing and update inventory systems simultaneously.

Enterprise-grade capabilities for mission-critical operations

Build once, use many times. Create workflow templates for common integration patterns and reuse them across projects and sites. OPC Router includes a growing library of pre-built templates for typical scenarios like database logging, cloud publishing, and alerting - giving you a head start on new projects.

Real-time visibility into all data flows. OPC Router's monitoring interface shows live connection status, data throughput, error rates, and trigger activity. Diagnose issues quickly with detailed logging and trace functionality. Performance counters help optimize configurations for maximum throughput.

Automate recurring tasks with flexible scheduling. Configure workflows to run at specific times, intervals, or based on shift calendars. Combine time-based and data-based triggers for sophisticated automation - like generating reports at shift end only if production occurred.

Centralized, encrypted storage of all connection credentials. Manage usernames, passwords, certificates, and API keys securely within OPC Router. Change credentials once and all workflows using that connection are updated automatically. Supports Windows authentication, certificate-based auth, and API tokens.

Deploy redundant OPC Router instances for critical applications. Primary/backup configurations with automatic failover ensure continuous data routing even if a server fails. Supports load balancing across multiple instances for high-throughput scenarios. Store-and-forward buffering prevents data loss during temporary outages.

Developed and continuously improved by inray Industriesoftware GmbH, a German company specializing in industrial automation software since 2006. OPC Router benefits from ongoing development, regular updates with new features and protocols, and dedicated technical support from automation experts.

Connect to virtually any industrial or enterprise system with OPC Router's extensive plug-in library

New plug-ins are continuously added. Don't see what you need?

Contact Us About Custom Plug-ins

Deploy in days, not months - without a single line of code.

Trusted by thousands of manufacturers worldwide

Over 10,000 installations worldwide across manufacturing, energy, building automation, and other industrial sectors. Trusted by Fortune 500 companies and small businesses alike.

Technical support from industrial automation experts who understand your challenges. Comprehensive documentation, training resources, and an active user community.

Reduce integration costs by 70-80% compared to custom development. Deploy projects in days instead of months. Lower ongoing maintenance costs with visual, self-documenting workflows.

Continuous development ensures support for emerging protocols and technologies. Regular updates keep your integration platform current without the need for costly upgrades or replacements.

Subscription License

Part #: 41303301-SUB

Buy NowSubscription License

Part #: 41303303-SUB

Buy NowSubscription License

Part #: 41303302-SUB

Buy NowJust like with subscriptions, you purchase a starting bundle of functionality and add modules later as required by simply paying for the added functionality.

With a perpetual license, you own the license forever, and annual payments are not required for it to keep functioning. Your initial purchase includes technical support and upgrades/updates/bug fixes for a year from purchase. Support & Maintenance can be renewed annually and is highly recommended for optimal, secure operation.

Below are some examples of perpetual licensing bundles. Many other starting bundles are available, so please contact us to discuss your exact application needs.

Advanced features like Redundancy, Enterprise+ and Store & Forward require additional licensing.

Perpetual License

Perpetual

Request QuotePerpetual License

Perpetual

Request QuotePerpetual License

Perpetual

Request QuoteJoin thousands of companies using OPC Router to connect their industrial systems without programming.